Egiyeni lokuqondisa cishe lazo zonke izimoto ezinamasondo, kunezinto ezidlulisa amandla ukusuka kumshini wokuqondisa kuya emasondweni - izinsimbi zokuqondisa.Konke mayelana nezinduku zokubopha, izinhlobo zazo ezikhona, ukuklama nokusebenza, kanye nokukhetha okulungile nokushintshwa kwalezi zingxenye - funda isihloko esihlongozwayo.

Yini i-tie rod?

Induku yokuqondisa - isici sokushayela komshini wokuqondisa wezimoto ezinamasondo (ngaphandle kwamagandaganda nezinye izinto ezinohlaka lokuphuka);Ingxenye ngendlela yenduku ene-joint yebhola (amahinge), okuqinisekisa ukudluliswa kwamandla kusuka kumshini wokuqondisa kuya kuma-levers ama-knuckles okuqondisa amasondo nakwezinye izingxenye zedrayivu yokuqondisa.

Ukuqondisa kwezimoto ezinamasondo kuhlukaniswe izingxenye ezimbili eziyinhloko: indlela yokuqondisa kanye nokushayela kwayo.I-steering mechanism ilawulwa yi-steering wheel, ngosizo lwalo kudalwa amandla okuchezukisa amasondo.La mandla adluliselwa emasondweni ngendlela yokushayela, okuwuhlelo lwezinduku nezinsimbi ezixhunywe ngamahinge.Enye yezingxenye eziyinhloko zedrayivu yizinduku zokubopha ezihlukile endaweni, ukuklama kanye nenjongo.

Izinsimbi zokuqondisa zinemisebenzi eminingi:

● Ukudluliswa kwamandla ukusuka kumshini wokuqondisa kuya ezingxenyeni ezihambisanayo zedrayivu futhi ngqo kuma-levers amaqupha okuqondisa amasondo;

● Ukubamba i-engeli ekhethiwe yokuzungezisa amasondo lapho wenza ukuqondisa;

● Ukulungiswa kwe-engeli yokuzungezisa kwamasondo esiteringi kuye ngendawo yesiteringi nokunye ukulungiswa kwegiya lokuqondisa ngokujwayelekile.

Izintambo zokubopha zixazulula umsebenzi obalulekile wokudlulisa amandla kusukela kumshini wokuqondisa kuya emasondweni aqondisayo, ngakho-ke, uma kwenzeka ukungasebenzi kahle, lezi zingxenye kufanele zishintshwe ngokushesha ngangokunokwenzeka.Kodwa ukuze ukhethe kahle i-thrust entsha, kuyadingeka ukuqonda izinhlobo ezikhona, imiklamo kanye nezici zalezi zingxenye.

Izinhlobo kanye nokusebenza kwezinduku zokubopha

Izinduku zokubopha zingahlukaniswa zibe izinhlobo eziningana ngokusho kwenhloso yazo, ukusebenziseka kanye nezinye izici zokuklama.

Ngokusebenza, kunezinhlobo ezimbili zokudonsa:

● Okwezinhlelo zokuqondisa ezisuselwe kuzikelemu nezinye izindlela zokuqondisa kanye nokushayela ngendlela ye-trapezoid yokuqondisa;

● Okwamasistimu okuqondisa asekelwe kuma-steering rack anedrayivu yesondo eqondile.

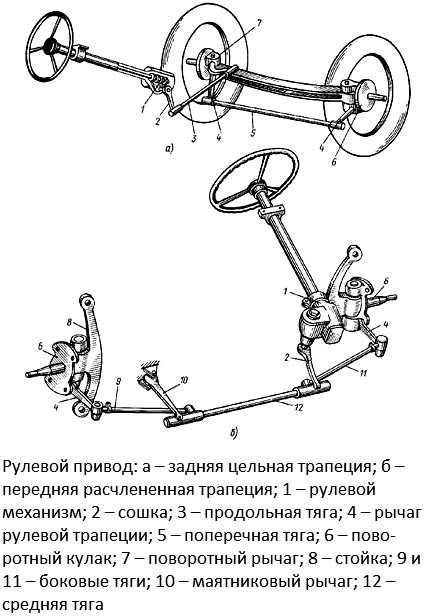

Ezinhlelweni zohlobo lokuqala (ezine-trapezoid zokuqondisa), kusetshenziswa izinduku ezimbili noma ezintathu, kuya ngohlobo lokumiswa kwe-axle eqondiwe kanye nohlelo lokuqondisa lwe-trapezoid:

● Ku-ekseli ene-ancient suspension: izinduku ezimbili - i-longitudinal eyodwa, evela ku-bipod yokuqondisa, neyodwa ephambanayo, exhunywe ezinsikeni zamaqunu okuqondisa amasondo;

● Ku-ekseli ene-suspension ezimele: izinduku ezintathu - i-longitudinal middle eyodwa (maphakathi), exhunywe ku-bipod ye-steering mechanism, kanye nezinhlangothi ezimbili ze-longitudinal longitudinal, ezixhunywe maphakathi kanye nezinsimbi zamaqunu okuqondisa amasondo.

Kukhona futhi izinketho zama-trapezoid ku-axle ene-suspension ezimele enezinduku ezimbili eziseceleni ezixhunywe ku-bipod yokuqondisa endaweni emaphakathi.Kodwa-ke, ukushayela kwesikimu esinjalo kuvame ukusetshenziswa kakhulu ekuqondiseni okusekelwe kuma-racks okuqondisa, achazwe ngezansi.

Izinhlobo nezinhlelo zokuqondisa kwe-trapezoid

Kumele kuqashelwe ukuthi ekuqondiseni i-trapezoids ye-axle ene-suspension ozimele, induku eyodwa yokubopha isetshenziswa ngempela, ihlukaniswe izingxenye ezintathu - ibizwa ngokuthi induku ehlakazekile.Ukusetshenziswa kothayi onqanyuliwe kuvimbela ukuchezuka okuzenzakalelayo kwamasondo ayisiteringi lapho ushayela kuma-bumps emgwaqeni ngenxa ye-amplitude ehlukene ye-oscillation yamasondo angakwesokudla nangakwesokunxele.I-trapezoid ngokwayo ingatholakala ngaphambili nangemuva kwe-axle yamasondo, esimweni sokuqala ibizwa ngokuthi ingaphambili, okwesibili - ngemuva (ngakho ungacabangi ukuthi "i-trapezoid yangemuva" iyigiya lokuqondisa elitholakala. i-asi yangemuva yemoto).

Ezinhlelweni zokuqondisa ezisekelwe ku-rack yokuqondisa, kusetshenziswa izinduku ezimbili kuphela - okuphambene kwesokudla nakwesobunxele ukushayela amasondo angakwesokudla nangakwesokunxele, ngokulandelana.Eqinisweni, lena i-trapezoid yokuqondisa enenduku ye-longitudinal ehlukanisiwe ene-hinge phakathi nendawo - lesi sixazululo senza kube lula ukuklama kokuqondisa, okwandisa ukuthembeka kwayo.Izinduku zalo mshini zihlala zinomklamo oyinhlanganisela, izingxenye zazo zangaphandle zivame ukubizwa ngokuthi amathiphu okuqondisa.

Izinduku zokubopha zingahlukaniswa ngamaqembu amabili ngokuya ngamathuba okushintsha ubude bazo:

● Okungalawulwa - izinduku zocezu olulodwa ezinobude obunikeziwe, zisetshenziswa kumadrayivu anezinye izinduku ezilungisekayo noma ezinye izingxenye;

● Okushintshekayo - izinti eziyinhlanganisela, okuthi, ngenxa yezingxenye ezithile, zingashintsha ubude bazo ngaphakathi kwemikhawulo ethile ukuze zilungise igiya lokuqondisa.

Ekugcineni, izinduku zingahlukaniswa ngamaqembu amaningi ngokuya ngokusebenza kwazo - ezimotweni namaloli, ezimotweni ezineziqondiso zamandla nezingenawo, njll.

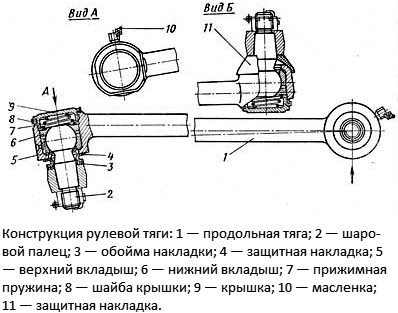

Idizayini yenduku yokubopha

Umklamo olula unezinduku ezingalawulwa - zisekelwe endongeni eyize noma yonke-metal yephrofayili (ingaba iqonde noma igobe ngokuhambisana nezici zokuklama zemoto), komunye noma womabili umkhawulo lapho amalunga ebhola atholakala khona.Amahinge awahlukaniseki, ahlanganisa umzimba onophini webhola otholakala ngaphakathi onentambo yenadi lomqhele kanye nembobo ephambanayo yephinikhodi ye-cotter;Ihinge ingavalwa ngebhuthi yerabha ukuvikela ukungcola namanzi.Ku-thrust transverse, izimbazo zeminwe yamalungu ebhola zitholakala endizeni efanayo noma zigudluzwe nge-engeli encane.Ku-thrust ye-longitudinal, izimbazo zezikhonkwane ze-hinge ngokuvamile zi-perpendicular komunye nomunye.

Idizayini ethize eyinkimbinkimbi kakhulu inezinduku eziphambanayo ezingalawulwa.Kulolu hlelo lokusebenza, izici ezengeziwe zinganikezwa:

I-Radiator nepulaki yethangi lokunweba elinama-valve ahlanganisiwe atholakala ku-eksisi efanayo

● Ezintini zama-ekseli ancike ku-suspension - imbobo noma ihinji yokuxhuma ku-bipod yokuqondisa;

● Ezintini zama-axle ane-suspension ezimele - izimbobo ezimbili ezihlelwe ngokulinganayo noma amahinge ukuze kuxhunywe izinduku eziseceleni;

● Kumarodi ezimoto ezine-hydrostatic steering (GORU) - ubakaki noma imbobo yokuxhuma entweni yesilinda se-hydraulic GORU.

Kodwa-ke, ama-trapezoid anengalo ye-pendulum asetshenziswa kabanzi ezimotweni eziningi - ezinhlelweni ezinjalo, i-trapezoid ephakathi nendawo emacebweni ayo inezimbobo zokufaka i-pendulum lever kanye ne-bipod yokuqondisa.

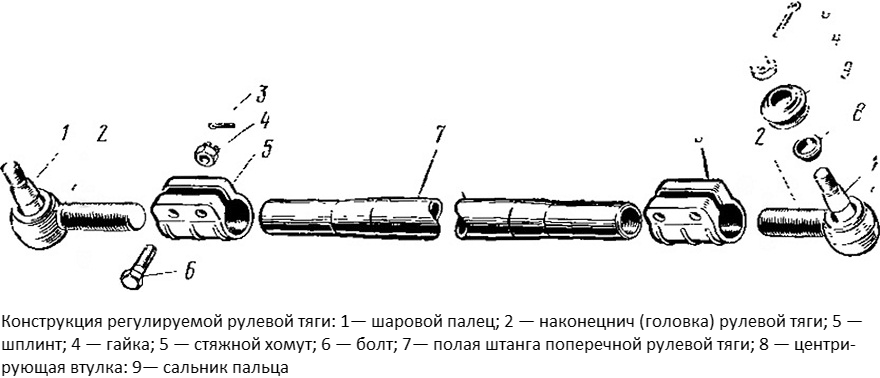

Izinduku zokubopha ezilungisekayo zihlanganisa izingxenye ezimbili eziyinhloko: induku ngokwayo kanye nethiphu yokuqondisa exhunywe kuyo.Ithiphu ngendlela eyodwa noma enye ingashintsha indawo yayo ngokuhlobene nokuphonseka, okukuvumela ukuthi ulungise ubude bengxenye yonke.Ngokuya ngendlela yokulungiswa, i-thrust ingahlukaniswa ngezinhlobo ezimbili:

● Ukulungiswa kwentambo ngokulungiswa kwe-locknut;

● Ukulungiswa ngochungechunge noma indlela ye-telescopic ngokulungiswa nge-clamp yokubopha.

Esimweni sokuqala, ithiphu inentambo efakwe ku-counter thread ekupheleni kwenduku, noma ngokuphambene nalokho, futhi ukulungiswa kusuka ekujikeni kwenziwa nge-locknut kuntambo efanayo.Esimweni sesibili, ithiphu ingaphinde ifakwe endongeni, noma ivele ifakwe kuyo, futhi ukulungiswa kusuka ekuphenduleni kwenziwa nge-clamp yokuqinisa endaweni yangaphandle yenduku.I-clamp yokuqinisa ingaba mncane futhi iqiniswe ngebhawodi eyodwa kuphela enamantongomane, noma ububanzi ngokuqiniswa kwamabhawodi amabili.

Idizayini yenduku yokubopha elungisekayo enezinsimbi zokubopha

Zonke izinduku zokubopha zincike komunye nomunye nakwezinye izingxenye zesistimu yokuqondisa - lokhu kuqinisekisa ukusebenza okuvamile kwesistimu ngesikhathi sokuguqulwa okwenzeka ngenkathi imoto ihamba.Izimbazo zamahinge ziyizikhonkwane zebhola, zigxilwe emigodini yezingxenye zokukhwelana ngamantongomane omqhele ahlanganiswe nezikhonkwane ze-cotter.

Izinduku zenziwe ngensimbi yamabanga ahlukahlukene, zingaba ne-coating yokuzivikela ngendlela yopende ovamile noma i-electroplating ngezinsimbi ezihlukahlukene - zinc, chromium nabanye.

Indlela yokukhetha nokushintsha induku yokubopha

Izinduku zokuqondisa zibhekene nemithwalo ebalulekile ngesikhathi sokusebenza kwemoto, ngakho-ke zisheshe zingasebenzi.Ngokuvamile, izinkinga ziphakama emalungeni ebhola, futhi izinduku nazo zingaphansi kokuguqulwa nokuqhekeka, okulandelwa ukubhujiswa kwengxenye.Ukungasebenzi kahle kwezinduku kungase kuboniswe ngokuhlehla emuva nokushaywa kwesondo lokuqondisa, noma, ngokuphambene nalokho, isondo eliqinile kakhulu, ukungqongqoza okuhlukahlukene ngenkathi ushayela, kanye nokulahlekelwa ukuzinza kwemoto (kuholela ekutheni ohlangothini).Lapho lezi zimpawu zivela, ukuqondisa kufanele kutholwe, futhi uma izinkinga ngezinduku zitholakala, zidinga ukushintshwa.

Ukushintshwa, kufanele ukhethe lezo zinduku zokuqondisa kanye namathiphu afakwe emotweni ngaphambili - lena ukuphela kwendlela yokuqinisekisa ukuthi ukuqondisa kuzosebenza kahle.Uma inkinga yenzeka kuphela ohlangothini olulodwa lwenduku noma ithiphu, kungcono ukushintsha lezi zingxenye ngamabili, ngaphandle kwalokho kukhona amathuba aphezulu kakhulu okuphuka kwenduku esondweni lesibili.

Ukushintshwa kwezinduku kufanele kwenziwe ngokuhambisana nemiyalelo yokulungisa nokugcinwa kwemoto.Imvamisa, lo msebenzi wehlela ekuphakamiseni imoto kujeke, ukudiliza izinduku ezindala (okungcono ukusebenzisa i-puller ekhethekile) nokufaka ezintsha.Ngemuva kokulungiswa, kunconywa ukulungisa ukuqondanisa kwesondo.Izinduku ezintsha kwezinye izimoto (ikakhulukazi amaloli) kufanele zigcotshwe ngezikhathi ezithile, kodwa ngokuvamile lezi zingxenye azidingi ukulungiswa phakathi nayo yonke impilo yazo yesevisi.

Ngokukhetha okulungile nokushintshwa kwezinduku zokubopha, ukushayela kuzoba okuthembekile nokuzethemba kuzo zonke izindlela zokushayela.

Isikhathi sokuthumela: Jul-26-2023