Kunoma iyiphi imoto kukhona amasistimu nemihlangano edinga ukulawula igesi noma umfutho we-liquid - amasondo, isistimu kawoyela wenjini, i-hydraulic system nabanye.Ukulinganisa ingcindezi kulezi zinhlelo, amadivaysi akhethekile aklanyelwe - ama-gauge okucindezela, izinhlobo nezinhlelo zokusebenza ezichazwe esihlokweni.

Iyini i-pressure gauge

Igeji yokulinganisa umfutho wemoto (kusuka kwelesiGreek elithi "manos" - loose, kanye "metreo" - measuring) iyithuluzi lokulinganisa umfutho wamagesi noketshezi kumasistimu namayunithi ahlukahlukene ezimoto.

Ukusebenza okujwayelekile nokuphephile kwezimoto, amabhasi, ogandaganda nezinye izinto ezisetshenziswayo, kuyadingeka ukulawula ukucindezelwa kwamagesi noketshezi ezinhlelweni ezahlukahlukene - emoyeni kumathayi, amasondo nezinhlelo zepneumatic, uwoyela enjini kanye nohlelo lwe-hydraulic, nabanye. .Ukuxazulula le nkinga, kusetshenziswa amadivaysi akhethekile - ama-gauges okucindezela.Ngokusho kokufundwa kwegeji yokucindezela, umshayeli uhlola ukusebenza kwalezi zinhlelo, ulungise izindlela zabo zokusebenza noma unqume ukulungiswa.

Ukuze uthole isilinganiso esifanele sokucindezela, kuyadingeka ukusebenzisa igeji yokucindezela enezici ezifanele.Futhi ukuze ukhethe idivayisi enjalo, kufanele uqonde izinhlobo zabo ezikhona nezici.

Izinhlobo nokuklama kwezikali zokucindezela

Izinhlobo ezimbili zamathuluzi okulinganisa umfutho asetshenziswa ezimotweni:

● Izikali zokucindezela;

● Izikali zokucindezela.

Amageji okucindezela amadivayisi anesici sokuzwa esakhelwe ngaphakathi esisebenzisana ne-medium okudinga ukulinganiswa ukucindezela kwayo.Ezimotweni, izikali zomfutho womoya zivame ukusetshenziselwa ukukala umfutho womoya emathayini amasondo kanye nohlelo lwe-pneumatic, kanye nokuhlola ukucindezelwa kumasilinda enjini.Izikali zomfutho kawoyela zisetshenziswa kancane, zingatholakala emishinini enohlelo oluthuthukisiwe lwama-hydraulic.

Izikali zokucindezela kungamadivayisi lapho into yokuzwa yenziwa ngendlela yenzwa eyirimothi.Ingcindezi ikalwa yisinzwa eguqula ubuningi bemishini ibe ekagesi.Isignali kagesi etholwe ngale ndlela ithunyelwa ku-gauge yokucindezela ye-pointer noma uhlobo lwedijithali.Izikali zokucindezela zingaba amafutha kanye ne-pneumatic.

Wonke amadivaysi ahlukaniswe ngamaqembu amabili ngokuya ngendlela yokulinganisa nokubonisa ulwazi:

● Izinkomba zemishini;

● Idijithali ye-elekthronikhi.

I-Mechanical tyre pressure gauge

I-electronic tire pressure gauge

Zombili izinhlobo zamageji omfutho zinedivayisi efanayo ngokuyisisekelo.Isisekelo sedivayisi siyisici esibucayi esithintana nendawo futhi sibona ukucindezela kwayo.I-transducer ihlotshaniswa nesici senzwa - idivayisi eguqula ubuningi bomshini owodwa (ingcindezi emaphakathi) ibe obunye ubuningi bomshini (ukuchezuka komcibisholo) noma ibe isignali kagesi.Idivayisi yenkomba ixhunywe kusiguquli - umcibisholo onokudayela noma isibonisi se-LCD.Zonke lezi zingxenye zibekwe endlini, lapho izingxenye ezifanelekayo nezisizayo (izinkinobho noma izinsimbi zokunciphisa ingcindezi, izibambo, izindandatho zensimbi nezinye) zikhona.

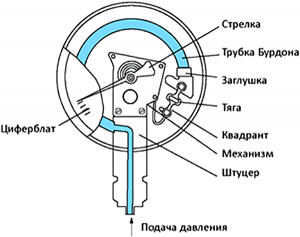

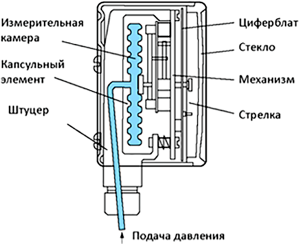

Ezokuthutha ngezimoto, kusetshenziswa izinhlobo ezimbili zamageji omfutho wemishini yokuguqula (intwasahlobo) - asuselwa kushubhu (Bourdon tube) neziphethu ezimise okwebhokisi (izimpophoma).

Isisekelo sedivayisi yohlobo lokuqala yi-tube yensimbi evaliwe ngesimo sendandatho yesigamu (i-arc), enye ingxenye yayo igxilwe ngokuqinile esimweni, kanti eyesibili ikhululekile, ixhunywe kusiguquli (ukudluliselwa indlela).I-transducer yenziwe ngendlela yesistimu yezintambo neziphethu ezixhunywe kumcibisholo.I-tube ixhunywe ku-fitting exhunywe ohlelweni ukuze kulinganiswe izingcindezi ezikulo.Njengoba ukucindezela kwanda, ithubhu livame ukuqondisa, umkhawulo walo wamahhala uyakhuphuka futhi udonse ama-levers omshini wokudlulisela, wona, ophazamisa umcibisholo.Indawo yomcibisholo ihambisana nenani lokucindezela ohlelweni.Lapho ukucindezela kuncipha, ithubhu libuyela endaweni yalo yokuqala ngenxa yokuqina kwalo.

Isisekelo sedivayisi yohlobo lwesibili yibhokisi lensimbi eboshiwe (izinsimbi) zomumo we-cylindrical - empeleni, lezi ziyizingqimba ezimbili eziyindilinga ezinothayela ezixhunywe ibhande elincane.Enkabeni yesisekelo esisodwa sebhokisi kukhona ithubhu yokuhlinzeka egcina ngokufaneleka, futhi isikhungo sesisekelo sesibili sixhunywe nge-lever ye-transmission mechanism.Njengoba ingcindezi ikhula, ama-diaphragm ayahluka ukusuka komunye nomunye, lokhu kususwa kulungiswa indlela yokudlulisela futhi kuboniswa ngokuhambisa umcibisholo eduze nokudayela.Lapho ukucindezela kuncipha, ulwelwesi, ngenxa yokunwebeka kwawo, lushintsha futhi futhi luthathe indawo yalo yasekuqaleni.

Idivayisi yegeji yokucindezela ene-tubular spring

(Bourdon tube)

Idivayisi yegeji yokucindezela enebhokisi lesiphethu

(igumbi)

Amageji engcindezi kagesi angahlonywa ngezinto zokuzwa zohlobo lwasentwasahlobo, kodwa namuhla izinzwa ezikhethekile zokucindezela okuhlangene zivame ukusetshenziswa eziguqula ukucindezela kwegesi noma uketshezi kube isignali kagesi.Lesi siginali iguqulwa yisekethe ekhethekile futhi iboniswe kunkomba yedijithali.

Ukusebenza, izici kanye nokusebenza kwezikali zokucindezela

Izikali zokucindezela ezenzelwe imishini yezimoto zingahlukaniswa zibe izinhlobo eziningana ngokuya nenjongo yazo:

● Amathayi aphathekayo namile - okulinganisa umfutho womoya emathayeni;

● I-pneumatic ephathekayo ukuhlola ukucindezelwa kwamasilinda enjini;

● I-pneumatic stationary yokulinganisa ingcindezi kumasistimu omoya;

● Amafutha okulinganisa umfutho kawoyela enjinini.

Ngokuya ngokusebenza kwezikali zokucindezela, izinhlobo ezahlukene zokufakwa kanye nokwakhiwa kwezindlu zisetshenziswa.Imishini ephathekayo ivamise ukuba nezindlu ezimelana nomthelela kanye nokufakwa okungenantambo (okunanyathiselwe), okumele, ukuze kuqinisekiswe ukucinana, kucindezelwe ku-valve yamasondo, ekhanda lenjini, njll. Emishinini enganyakazi, kusetshenziswa okokufaka okucushiwe okunophawu olungeziwe, kulokho. ama-gauge okucindezela kanye nezikali zokucindezela, izibani ze-backlight nezixhumi zokuxhuma kwazo nazo zingatholakala.

Amadivayisi angase abe nemisebenzi ehlukahlukene eyisizayo:

● Ukuba khona kweshubhu lensimbi elinwetshiwe noma ipayipi eliguquguqukayo;

● Ukuba khona kwevalvu yokulungisa umphumela wokulinganisa (ngokuvumelana nalokhu, kukhona nenkinobho yokukhulula ukucindezela nokumisa idivayisi ngaphambi kokulinganisa okusha);

● Ukuba khona kwama-deflators - ama-valve aguquguqukayo okunciphisa ukucindezela okulawulwayo ngokulawulwa kanyekanye nge-gauge yokucindezela;

● Izici ezengeziwe ezihlukahlukene zemishini kagesi - ukukhanya okungemuva, inkomba yomsindo nokunye.

Ngokuqondene nezici, ezimbili zazo zibalulekile ezilinganisweni zokucindezela kwezimoto - ingcindezi yokugcina (ububanzi bezingcindezi ezilinganisiwe) kanye nesigaba sokunemba.

Ingcindezi ilinganiswa ngamakhilogremu-amandla ngesentimitha-skwele (kgf/cm²), umkhathi (1 atm = 1 kgf/cm²), amabha (1 ibha = 1.0197 atm.) kanye namandla ephawundi ngeyintshi yesikwele (psi, 1 psi = 0.07 atm.).Ekudayilweni kwegeji yokucindezela, iyunithi yokulinganisa kufanele ikhonjiswe, kwezinye izikali zokucindezela kwezikhombisi kunezilinganiso ezimbili noma ezintathu ngesikhathi esisodwa, ezilinganiswe ngamayunithi ahlukene okulinganisa.Kumageji e-electronic pressure, ungathola umsebenzi wokushintsha iyunithi yesilinganiso eboniswa esibukweni.

Igeji yokucindezela ene-deflator

Isigaba sokunemba sinquma iphutha elethulwa yigeji yokucindezela phakathi nokulinganisa.Isigaba sokunemba sedivayisi sihambisana nobukhulu obubodwa ukusuka kububanzi obungu-0.4, 0.6, 1.0, 1.5, 2.5 kanye no-4.0, inombolo encane, ukuphakama kokunemba.Lezi zibalo zibonisa iphutha elikhulu njengephesenti lebanga lokulinganisa ledivayisi.Isibonelo, igeji yokucindezela kwesondo enomkhawulo wokulinganisa wama-atmospheres angu-6 kanye nekilasi lokunemba elingu-0.5 "lingakhohlisa" kuphela i-atmospheres engu-0.03, kodwa igeji yokucindezela efanayo yesigaba sokunemba esingu-2.5 izonikeza iphutha le-atmospheres engu-0.15.Ikilasi lokunemba livame ukuboniswa ekushayeni ucingo, le nombolo ingase yandulelwe yizinhlamvu KL noma CL.Izigaba zokunemba zamageji okucindezela kufanele zihambisane ne-GOST 2405-88.

Indlela yokukhetha nokusebenzisa i-pressure gauge

Uma uthenga i-gauge yokucindezela, kuyadingeka ukucabangela uhlobo nezici zokusebenza.Indlela elula ukukhetha i-gauge yokucindezela eyakhelwe kudeshibhodi yemoto - kulokhu, udinga ukusebenzisa idivayisi yohlobo kanye nemodeli enconywa yi-automaker.Ukukhetha ama-gauge okucindezela okumile kumasistimu we-hydraulic kanye ne-pneumatic nakho kulula - udinga ukusebenzisa idivayisi enohlobo olufanele lokulinganisa nokulinganisa ingcindezi.

Ukukhethwa kwamageji okucindezela amathayi kubanzi kakhulu futhi kuhluke kakhulu.Ezimotweni zabagibeli, idivayisi enomkhawulo wokulinganisa we-atmospheres efika ku-5 yanele (njengoba ingcindezi evamile yesondo ingu-2-2.2 atm., futhi "kuma-stowaways" - kufika ku-4.2-4.3 atm.), amaloli, i- idivayisi ye-7 noma ngisho ne-11 atmospheres ingadingeka.Uma ngokuvamile kufanele ushintshe ukucindezela kwesondo, kungcono ukusebenzisa i-gauge yokucindezela nge-deflator.Futhi ukukala ingcindezi kumasondo e-gable amaloli, idivayisi ene-tube yokwandisa noma i-hose izoba yisixazululo esihle kakhulu.

Ukulinganisa nge-gauge yokucindezela kufanele kwenziwe ngokuhambisana nemiyalelo enamathiselwe kuyo.Lapho ukala, kubalulekile ukuqinisekisa ukuthi isilinganisi socingo cindezelwe ngokuvikelekile endaweni yokubala noma imbobo, ngaphandle kwalokho ukunemba kokufundwayo kungase konakale ngenxa yokuvuza komoya.Ukufakwa kwezikali zokucindezela ezimile kuvunyelwe kuphela ngemva kokukhululwa kwengcindezi ohlelweni.Ngokukhetha okulungile nokusetshenziswa kwegeji yokucindezela, umshayeli uzohlala enolwazi mayelana nokucindezela komoya nowoyela, futhi uzokwazi ukuthatha izinyathelo zokuxazulula izinkinga ngesikhathi.

Isikhathi sokuthumela: Jul-12-2023