Ukuqapha ingcindezi ohlelweni lokuthambisa kungenye yemibandela yokusebenza okuvamile kwenjini evuthayo yangaphakathi.Izinzwa ezikhethekile zisetshenziselwa ukukala ingcindezi - funda konke mayelana nezinzwa zokucindezela uwoyela, izinhlobo zazo, ukwakheka, isimiso sokusebenza, kanye nokukhetha kwazo okulungile nokushintshwa esihlokweni.

Iyini inzwa yomfutho kawoyela?

Inzwa yokucindezela uwoyela iyisici esibucayi se-instrumentation kanye namadivayisi we-alamu wohlelo lokuthambisa lwezinjini ezivuthayo zangaphakathi ezibuyiselayo;Inzwa yokulinganisa ingcindezi ohlelweni lokuthambisa nokubonisa ukwehla kwayo ngaphansi kwezinga elibalulekile.

Izinzwa zomfutho kawoyela zenza imisebenzi emibili esemqoka:

• Ukuxwayisa umshayeli ngomfutho ophansi kawoyela ohlelweni;

• I-alamu mayelana nowoyela ophansi / ongenawo ohlelweni;

• Ukulawulwa komfutho kawoyela ophelele enjinini.

Izinzwa zixhunywe kulayini oyinhloko kawoyela wenjini, okuvumela ukuthi uqaphe umfutho kawoyela kanye nokuba khona kwawo ohlelweni lukawoyela (lokhu kukuvumela ukuthi uhlole ukusebenza kwepompo likawoyela, uma kungasebenzi kahle, uwoyela umane ukwenze. ungangeni umugqa).Namuhla, izinzwa zezinhlobo ezahlukene nezinjongo zifakwe ezinjini, okudingeka zichazwe ngokuningiliziwe.

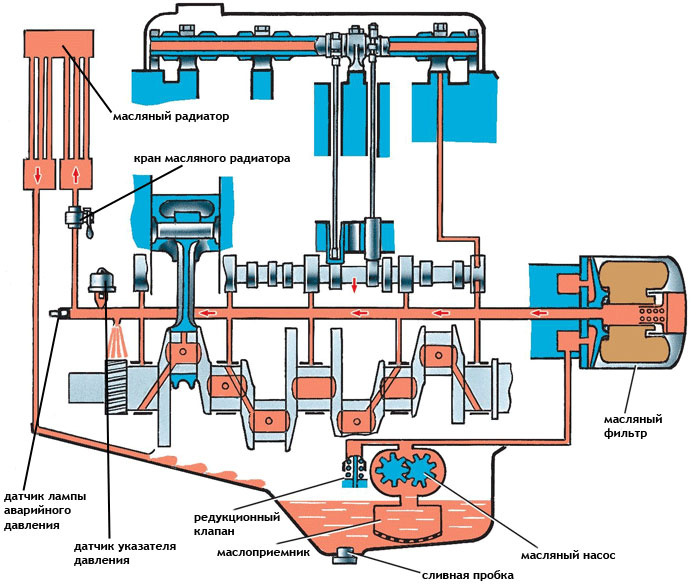

Isistimu yokugcoba injini kanye nendawo yezinzwa zokucindezela kuyo

Izinhlobo, ukuklama kanye nesimiso sokusebenza kwezinzwa zokucindezela uwoyela

Okokuqala, zonke izinzwa zokucindezela zihlukaniswe zibe izinhlobo ezimbili ngokwenhloso yazo:

• Inzwa ye-alamu (inzwa ye-alamu yokwehla kwengcindezi kawoyela eziphuthumayo, "inzwa esibani");

• Inzwa yokulinganisa umfutho kawoyela ophelele ("inzwa kudivayisi").

Amadivayisi ohlobo lokuqala asetshenziswa ohlelweni lwe-alamu lokwehla okubucayi ekucindezelweni kwamafutha, aqala kuphela lapho ukucindezela kwehla ngaphansi kwezinga elithile.Izinzwa ezinjalo zixhunywe kumishini yokubonisa yomsindo noma yokukhanya (ibhaza, isibani kudeshibhodi), exwayisa umshayeli mayelana nomfutho ophansi / izinga likawoyela enjinini.Ngakho-ke, lolu hlobo lwedivayisi luvame ukubizwa ngokuthi "izinzwa ngesibani ngasinye".

Izinzwa zohlobo lwesibili zisetshenziswa ohlelweni lokulinganisa umfutho kawoyela, zisebenza phezu kwalo lonke uhla lokucindezela ohlelweni lokugcoba injini.Lezi zinsimbi ziyizici ezibucayi zezinsimbi zokulinganisa ezihambisanayo (i-analog noma idijithali), izinkomba zazo ezivezwa kudeshibhodi futhi zibonise umfutho wamanje kawoyela enjinini, yingakho zivame ukubizwa ngokuthi "izinzwa emshinini".

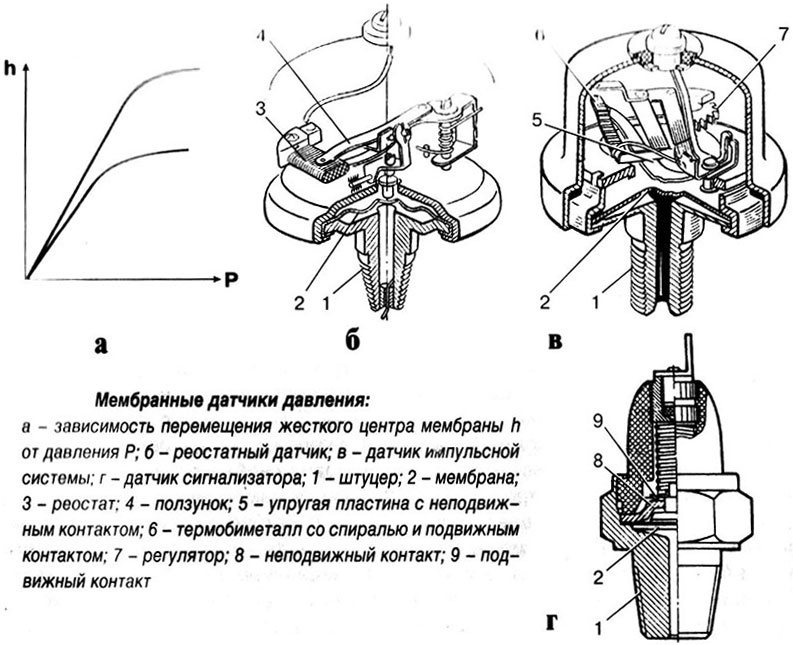

Zonke izinzwa zokucindezela uwoyela zanamuhla ziyi-diaphragm (diaphragm).Kunezingxenye ezintathu eziyinhloko kule divayisi:

• Umgodi ovalekile uvalwe ngolwelwesi lwensimbi oluguquguqukayo (diaphragm);

• Indlela yokudlulisa;

• Isiguquli: isignali yemishini eya kugesi.

I-cavity ene-diaphragm ixhunywe kulayini omkhulu kawoyela wenjini, ngakho-ke ihlala igcina umfutho kawoyela ofanayo njengakulayini, futhi noma yikuphi ukuguquguquka kwengcindezi kubangela ukuthi i-diaphragm iphambuke endaweni yayo emaphakathi.Ukuphambuka kwe-membrane kubonakala ngomshini wokudlulisa futhi kunikezwa ku-transducer, ekhiqiza isignali kagesi - lesi siginali sithunyelwa kudivayisi yokulinganisa noma iyunithi yokulawula kagesi.

Namuhla, izinzwa zokucindezela uwoyela zisebenzisa izindlela zokudlulisa kanye neziguquli ezihlukile ekwakhiweni nasekusebenzeni, sezizonke izinhlobo ezine zamadivayisi zingahlukaniswa:

Izinhlobo eziyinhloko ze-diaphragm (diaphragm) izinzwa zokucindezela kwamafutha

Namuhla, izinzwa zokucindezela uwoyela zisebenzisa izindlela zokudlulisa kanye neziguquli ezihlukile ekwakhiweni nasekusebenzeni, sezizonke izinhlobo ezine zamadivayisi zingahlukaniswa:

• Inzwa yohlobo lokuxhumana kuphela izinzwa zedivayisi yokubonisa ("esibani");

• Inzwa ye-Rheostat;

• Inzwa ye-Pulse;

• Inzwa ye-Piezocrystalline.

Idivaysi ngayinye inezici zayo zokuklama kanye nesimiso sokusebenza.

Xhumana nenzwa yomfutho kawoyela (isibani ngasinye)

Inzwa yohlobo lokuxhumana.Idivayisi ineqembu loxhumana naye - othintana naye osusekayo otholakala kulwelwesi, kanye noxhumana naye ogxilile oxhunywe kumzimba wedivayisi.Isikhundla sabathintana nabo sikhethwe ngendlela yokuthi ekucindezelweni kwamafutha okuvamile ohlelweni othintana nabo bavulekile, futhi ngokucindezela okuphansi bavaliwe.I-threshold pressure isethwe yi-spring, kuya ohlotsheni nemodeli yenjini, ngakho-ke izinzwa zohlobo lokuxhumana azishintshi ngaso sonke isikhathi.

Inzwa ye-Rheostat.Idivayisi ine-rheostat yocingo engashintshi kanye nesilayidi esixhunywe kulwelwesi.Lapho ulwelwesi luchezuka endaweni emaphakathi, isilayidi sizungeza i-axis ngokusebenzisa isihlalo esinyakazayo futhi sishelela eduze kwe-rheostat - lokhu kuholela ekushintsheni kokumelana kwe-rheostat, eqashwe idivayisi yokulinganisa noma iyunithi ye-electronic.Ngakho-ke, ukuguqulwa kokucindezela kwamafutha kubonakala ekushintsheni kokumelana kwenzwa, okusetshenziselwa izilinganiso.

Inzwa ye-Pulse.Idivayisi ine-thermobimetallic vibrator (i-transducer) enoxhumano oluqinile nolwelwesi.Isidlidlizi siqukethe othintana nabo ababili, oyedwa wabo (ongaphezulu) wenziwa ngepuleti le-bimetallic elinenxeba lekhoyili yokushisa kuyo.Esimweni esibandayo, ipuleti ye-bimetallic iqondiswe futhi ivaliwe ngokuthintana okuphansi - okwamanje igeleza ngesifunda esivaliwe, kufaka phakathi ikhoyili yokushisa.Ngokuhamba kwesikhathi, i-spiral ishisa ipuleti ye-bimetallic, iyagoba futhi isuke kude nokuxhumana okuphansi - isifunda sivula.Ngenxa yokuphumula kwesifunda, i-spiral iyeka ukushisa, ipuleti ye-bimetallic ipholisa phansi futhi iqondise - isifunda sivala futhi futhi inqubo iqala futhi.Ngenxa yalokho, ipuleti le-bimetallic lihlala lidlidliza futhi ijika elishintshayo lemvamisa ethile liyakhiwa ekuphumeni kwenzwa.

Ukuthintana okuphansi kwenzwa kuxhunywe ku-diaphragm, okuthi, kuye ngokucindezela kwamafutha, kuphambuke endaweni ephakathi phezulu noma phansi.Endabeni yokuphakamisa i-diaphragm (ngokwanda kwengcindezi yamafutha), ukuthintana okuphansi kuyakhuphuka futhi kucindezelwe kanzima ngokumelene nepuleti ye-bimetallic, ngakho-ke imvamisa yokudlidliza iyancipha, othintana nabo basesimweni esivaliwe isikhathi eside.Uma i-membrane yehliswa, ukuthintana okuphansi kuyasuka ku-bimetallic plate, ngakho-ke imvamisa yokudlidliza iyanda, othintana nabo basendaweni evaliwe isikhathi esincane.Ukushintsha ubude besikhathi soxhumana nabo esimweni esivaliwe (okungukuthi, ukushintsha imvamisa yamanje eshintshanayo ekuphumeni kwenzwa) futhi kusetshenziswa idivayisi ye-analog noma iyunithi ye-elekthronikhi ukukala ingcindezi kawoyela enjinini.

Inzwa ye-Piezocrystalline.Le nzwa ine-piezocrystalline transducer exhunywe kulwelwesi.Isisekelo se-transducer yi-resistor ye-piezocrystalline - i-crystal enezakhiwo ze-piezoelectric, ezindizeni ezimbili ezinikezwa amandla aqondile, futhi izindiza ze-perpendicular zixhunywe kulwelwesi kanye nepuleti eyisisekelo engaguquki.Lapho ingcindezi kawoyela ishintsha, i-membrane isuka endaweni yayo evamile, okuholela ekushintsheni kwengcindezi ku-resistor piezocrystalline - ngenxa yalokho, izakhiwo zokuqhuba ze-resistor futhi, ngokufanele, ukushintsha kwayo ukumelana.Ushintsho lwamanje ekuphumeni kwenzwa lusetshenziswa iyunithi yokulawula noma inkomba ukukala ingcindezi kawoyela enjinini.

Zonke izinzwa, kungakhathalekile ukuthi ziluphi uhlobo, zinekesi lensimbi eyi-cylindrical, ukufakwa okufakwe imicu kunikezwa ngaphansi kwendlu ukuze kuxhunywe kulayini kawoyela (ama-washer okuvalwa asetshenziselwa ukuvala), futhi othintana naye wokuxhuma ohlelweni lukagesi utholakala. phezulu noma ohlangothini.Ukuthintana kwesibili yindlu, ngokusebenzisa ibhulokhi yenjini exhunywe emhlabathini wesistimu kagesi.Kukhona futhi i-hexagon emzimbeni yokukhweza nokudiliza inzwa kusetshenziswa isikrufu esivamile.

Izinkinga zokukhetha nokushintshwa kwezinzwa zomfutho kawoyela

Izinzwa zomfutho kawoyela (ama-alamu kanyeizilinganiso zokucindezela) zibalulekile ukuqapha ukusebenza kwenjini, ngakho-ke uma zihluleka, kufanele zishintshwe - njengomthetho, azikwazi ukulungiswa.Isidingo sokushintsha inzwa singase siboniswe ngokufundwa okungalungile kwedivayisi noma ukusebenza njalo kwenkomba kudeshibhodi.Uma izinga lamafutha ohlelweni livamile, futhi azikho izinkinga ngenjini, khona-ke udinga ukufaka esikhundleni senzwa.

Ukuze kufakwe esikhundleni, kubalulekile ukukhetha izinzwa kuphela zalezo zinhlobo namamodeli anconywe umenzi wenjini.Ukusetshenziswa kwemodeli yenzwa ehlukile kungase kuholele ekwephuleni ukufundwa kwethuluzi lokulinganisa noma inkomba kudeshibhodi.Lokhu kuyiqiniso ikakhulukazi ezinzwa ze-alamu - ngokuvamile azilungiseki futhi zisethelwa kukucindezela okuthile embonini.Ngezinzwa zokucindezela kwamafutha, isimo sihlukile - ezimweni eziningi kungenzeka ukusebenzisa ezinye izinhlobo namamodeli wamadivayisi, kusukela idivayisi yokulinganisa noma iyunithi yokulawula i-elekthronikhi inikeza ikhono lokulungisa (ukulinganisa) inzwa entsha.

Ukushintsha inzwa yomfutho kawoyela kulula kakhulu.Umsebenzi kufanele wenziwe kuphela ngenjini emile futhi ebandayo, ngoba kulokhu akukho mafutha emgqeni omkhulu wamafutha (noma kuncane kakhulu), futhi ngeke kube khona ukuvuza lapho inzwa idilizwa.Inzwa imane idinga ukukhishwa isikulufe ngokhiye, futhi idivayisi entsha kufanele ikrufulwe endaweni yayo.Iwasha yokuvala uphawu kufanele ifakwe ku-sensor fitting, ngaphandle kwalokho isistimu ingase ilahlekelwe ukuqina kwayo.

Ngokukhetha okulungile nokushintshwa kwenzwa, isistimu ye-alamu yokwehla komfutho kawoyela ebalulekile kanye nesistimu yokulinganisa umfutho kawoyela wenjini izosebenza ngokwethembeka, inikeze ukuqapha okudingekayo kwesimo seyunithi yamandla.

Isikhathi sokuthumela: Aug-18-2023