Ekulungisweni kwamanje kwezinjini ze-KAMAZ, kunikezwa uhlelo lokupholisa uwoyela, olwakhiwe kuyunithi eyodwa - isishintshi sokushisa samafutha.Funda konke mayelana nalezi zingxenye, izinhlobo zazo, ukuklama, isimiso sokusebenza nokusebenziseka, kanye nokukhetha okulungile, ukulungiswa nokushintshwa kwezishintshi zokushisa kulesi sihloko.

Yini isishintshi sokushisa samafutha e-KAMAZ?

Isishintshi sokushisa uwoyela (i-liquid-oil heat exchanger, i-LMT) iyunithi yokuthambisa kanye nezinhlelo zokupholisa zamayunithi amandla edizili anamandla amakhulu;Isishintshi sokushisa esiklanywe ngokukhethekile esakhelwe ohlelweni lokupholisa uketshezi lwenjini, oluhlinzeka ngokupholisa uwoyela wenjini ngenxa yokushintshisana kokushisa nokugeleza kokupholisa.

Isistimu yokugcoba yamayunithi edizili e-KAMAZ anamandla asebenza ezimweni ezinzima, amafutha ahlala evezwe emazingeni okushisa aphezulu futhi kancane kancane alahlekelwa izimfanelo zawo.Ezinhlotsheni ezithile, uwoyela wenjini ungashisa ngokweqile, okuholela ekwehleni kwe-viscosity yawo kanye nokuthambisa, kanye nokubola okukhulu nokutubeka.Ekugcineni, uwoyela oshise ngokweqile uphazamisa ukusebenza kwenjini futhi ungabangela nokuba ihluleke.Le nkinga ixazululwa ngokwethula isici sokupholisa uwoyela - isishintshi sokushisa - ohlelweni lokuthambisa lwezinjini ze-KAMAZ.

Isishintshi sokushisa samafutha siyingxenye ebalulekile yokugcoba injini kanye nezinhlelo zokupholisa, siqinisekisa ukususwa kokushisa okudlulele emafutheni ngenxa yokushintshana kokushisa okusebenzayo nokugeleza kwewasha epholile (okupholile).Kungakho amadivaysi alolu hlobo abizwa ngokuthi ama-liquid-oil heat exchangers, noma i-LMT.Le yunithi yenza imisebenzi eminingana:

- Ukupholisa ingxenye kawoyela ekushiseni kwenjini okungaphansi kwamadigri ayi-100;

- Ukupholisa wonke amafutha angena enjini ekushiseni okuphakathi kuka-100-110 degrees;

- Ukunciphisa ukusetshenziswa kukawoyela kokumosha nokwelula impilo yawo;

- Ukuqinisekisa izinga lokushisa elilungile lezinhlelo ezihlukahlukene zenjini - ngenxa ye-LMT, izinga lokushisa likawoyela alilokothi lehle ngaphansi kwezinga lokushisa elipholile, elinomthelela ekushiseni okufanayo kwezingxenye zenjini, ukunciphisa ukucindezeleka kwemishini, njll.;

- Ukwenza lula ukwakheka kwesistimu yokupholisa uwoyela kanye nokunciphisa izindleko zenjini ngenkathi kuqinisekiswa izici ezijwayelekile zokusebenza kwayo.

Namuhla, ama-heaters afakwe ezinjini eziningi ze-KAMAZ ezihlangabezana nezindinganiso ze-Euro-2 nangaphezulu, zidlala indima ebalulekile ekuqinisekiseni izici ezijwayelekile zeyunithi yamandla kuzo zonke izindlela zokusebenza.Umshini wokushisa ongalungile kufanele ulungiswe noma ushintshwe ngokuphelele ngokushesha ngangokunokwenzeka, kodwa ngaphambi kokuthenga ingxenye entsha, kufanele uqonde ukuklama nokusebenza kwalawa madivayisi.

Idizayini kanye nesimiso sokusebenza kwezishintshi zokushisa zamafutha e-KAMAZ

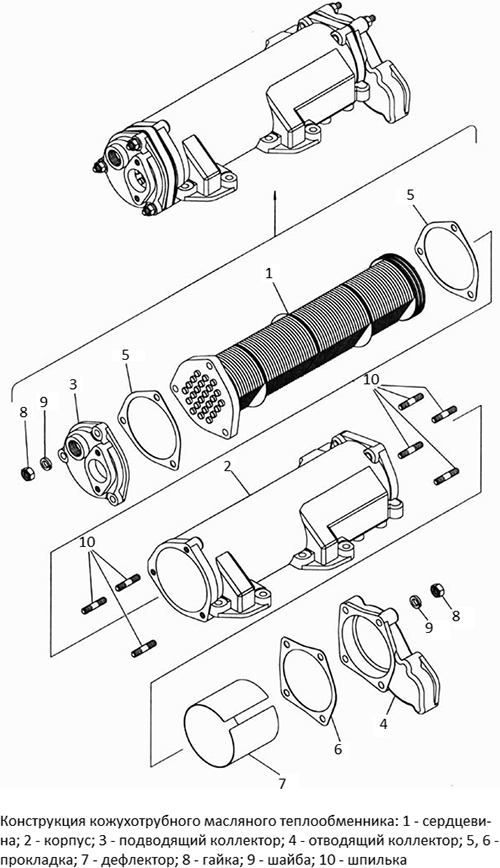

Ezinjinini ze-KAMAZ, kusetshenziswa uhlobo lwegobolondo neshubhu kuphela (i-tubular) uhlobo lwegobolondo neshubhu (i-tubular) lokuguqulwa okuhlukahlukene olusetshenziswayo njengamanje.Ngokwesakhiwo, le yunithi ilula kakhulu, iqukethe izingxenye ezilandelayo:

● Umzimba (ibhokisi);

● Ingqikithi ene-deflector;

● I-Inlet ehlukahlukene;

● Khipha ngokuningi.

Isisekelo sokuklama umzimba we-aluminium cylindrical (i-casing), odongeni lapho iziteshi nezindawo zokugcwalisa zenzelwe ukuxhuma ku-block filter yamafutha (ukufakwa kwenziwa ngama-gaskets).Iziphetho ze-casing zivaliwe ngezembozo ezikhethekile ezinama-nozzles - i-inlet ne-outlet manifolds, eyokuqala ihlinzeka ngokupholisa kusuka ebhantshini lamanzi le-cylinder block ngaphakathi kwendlu, kanti eyesibili idlulisela uketshezi emuva ohlelweni lokupholisa injini.Ukubhoboza namashaneli kwenziwa emzimbeni ukuze kufakwe ama-bypass valves, aqinisekisa ukuthi uwoyela udlula umshini wokushisa lapho umnyombo wawo uvalekile.

I-core ifakwe ngaphakathi kwekesi - ukuhlanganiswa kwamashubhu ethusi anezindonga ezincane noma zethusi afakwe ephaketheni lamapuleti ensimbi aphambene.Emgogodleni kukhona amapuleti amahlanu anengxenye ephumayo, ehlukanisa yonke ingxenye ibe izingxenye ezine, okunikeza ushintsho ekuqondeni kokugeleza kwamafutha.Ngakolunye uhlangothi lomnyombo kukhona i-flange, okuthi, ngesikhathi sokufakwa, iphumule ekugcineni komzimba, ngakolunye uhlangothi i-flange inobubanzi obufana nokulingana ngokuqinile ku-casing, futhi kukhona ama-O-rings ambalwa. yona.Lo mklamo uqinisekisa ukuhlukaniswa kokugeleza kokupholisa namafutha, kuvimbele ukuthi zingaxubani.Futhi ukuze uthole isiqondiso esifanele sokugeleza kwamafutha, i-deflector itholakala ohlangothini olulodwa lomgogodla - indandatho yensimbi evulekile ene-slot.

Idizayini yesishintshi sokushisa samafutha e-KAMAZ

Ku-LMT ehlanganisiwe, kwakheka isishintshi sokushisa esinokugeleza okubili okukodwa: isipholile sigeleza ngamashubhu ayinhloko, futhi uwoyela ugeleza esikhaleni esiphakathi kwamashubhu nezindonga ze-casing.Ngenxa yokuhlukaniswa kwengqikithi ibe yizigaba ezine, indlela yokugeleza kawoyela iyanda, okufeza ukudluliselwa kokushisa okuphumelelayo kwe-coolant.

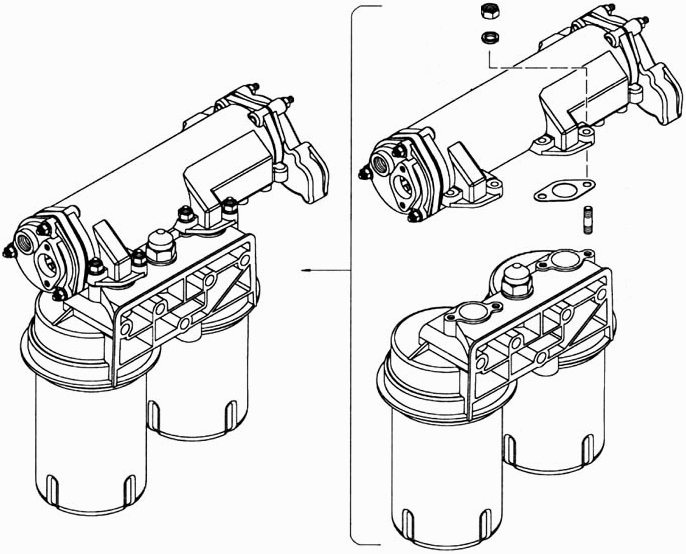

I-LMT ifakwe emshinini wokuhlanganisa injini ngebhulokhi yokuhlunga uwoyela (i-valve ye-thermopower elawula ukugeleza kukawoyela ngesishintshi sokushisa nayo ikhona lapha), ukuhlinzekwa kwayo kanye nokuphuma okuningi kwayo kuxhunywe kumapayipi ahambisanayo kubhulokhi yesilinda.Emiklamo eminingi, i-manifold yokuhlinzeka ixhunywe kubhulokhi ngokusebenzisa ipayipi elifushane, futhi i-manifold yokukhipha ixhunywe ngokusebenzisa indawo yokugcwalisa.

I-LMT isebenza kanje.Lapho izinga lokushisa kwenjini lingaphansi kwama-degrees angu-95, i-valve yamandla ashisayo ivaliwe, ngakho wonke ukugeleza kwamafutha kusuka empompini yamafutha kudlula izihlungi futhi kungena ngokushesha ohlelweni lokugcoba injini.Lapho izinga lokushisa likhuphuka ngaphezu kwama-degrees angu-95, i-valve iyavuleka, futhi ingxenye yamafutha avela ezihlungi ithunyelwa ku-LMT - lapha idlula ngaphakathi kwe-casing ezungeze umgogodla, ikhiphe ukushisa okwedlulele ku-coolant edlula amapayipi, futhi kuphela. bese ingena ohlelweni lokugcoba injini.Lapho izinga lokushisa likhuphuka ngaphezu kwama-degree angu-100, i-valve eshisayo iqondisa konke ukugeleza kwamafutha kusuka ezihlungi kuya ku-LMT.Uma nganoma yisiphi isizathu izinga lokushisa lenjini lidlule amadigri angu-115, ukupholisa uwoyela ku-LMT kungasebenzi futhi kungenzeka ukushisa ngokweqile - inkomba ehambisanayo kudeshibhodi ixwayisa ngokuqala kwesimo esiphuthumayo.

Ukusebenza kokushintshanisa ukushisa kwamafutha ezimotweni ze-KAMAZ

Ama-LMT afakwe kuphela ku-KAMAZ 740 injini yedizili yokuguqulwa okuhlukahlukene kwe-Euro-2, 3 no-4 amakilasi emvelo.Izinhlobo ezimbili zokushintsha ukushisa zisetshenziswa namuhla:

● Inombolo yekhathalogi 740.11-1013200 - ukuguqulwa okufushane;

● Inombolo yekhathalogi 740.20-1013200 ingukuguqulwa okude.

Umehluko phakathi kwalezi zingxenye usekuklanyweni kwabaqoqi futhi, ngenxa yalokho, endleleni yokuxhuma ohlelweni lokupholisa.Ku-LMT emfushane, i-manifold yokukhipha inendawo yokugcwalisa kuphela ekugcineni yokunamathisela ipayipi kusetshenziswa amabhawudi noma izikhonkwane.Ama-Heat exchangers anenqwaba enjalo akhona yonke indawo, afanele izinjini eziningi ze-KAMAZ zamakilasi ahlukahlukene emvelo.Ku-LMT ende e-outlet manifold kukhona ipayipi yokuxhuma i-hose nge-clamp yensimbi.Uma kungenjalo, zombili izingxenye ziyefana futhi zingaxhunywa kumaqoqo okuhlunga ajwayelekile.

Ukufakwa kwesishintshi sokushisa samafutha e-KAMAZ kuyunithi yesihlungi samafutha

Futhi, ezingxenyeni zomshini wokushisa, ngenxa yezinqubo zokugqwala noma umonakalo, imifantu nemifantu kwenzeka lapho amafutha angena khona kupholisa.Inkinga efanayo ibonwa lapho izakhi zokuvala zigugile noma zonakalisiwe.Kulokhu, i-LMT kufanele ilungiswe noma ishintshwe ngokuphelele.Namuhla, kukhona amakhithi wokulungisa ahlukahlukene emakethe aqukethe ama-gaskets, ama-cores, ama-manifolds nezinye izingxenye.Uma ukulungiswa kungenakwenzeka noma kungenakwenzeka, khona-ke kuyadingeka ukufaka esikhundleni ngokuphelele ingxenye.Wonke umsebenzi wenziwa ngokuhambisana nemiyalelo yokukhanda nokugcinwa kwemoto.Ngaphambi kokulungiswa, i-coolant kanye nengxenye yamafutha iyakhishwa, emva kokushintshwa, konke uketshezi kulethwa ezingeni elifunayo.Kamuva, i-LMT idinga kuphela ukuhlolwa okuvamile nokuqinisekiswa kwamavalvu phakathi nokugcinwa kwesimiso ngasinye.

Uma isishintshi sokushisa sikhethiwe futhi sifakwe ngendlela efanele, khona-ke amafutha enjini azohlala enezinga lokushisa elilungile, eqinisekisa ukusebenza kahle kweyunithi yamandla.

Isikhathi sokuthumela: Jul-13-2023