Ama-shafts aphuma kumayunithi okudlulisela kanye nezinye izinqubo zemoto angabangela ukuvuza nokungcoliswa kwamafutha - le nkinga ixazululwa ngokufaka ama-oil seal.Funda konke mayelana nezimpawu zokushayela, ukuhlukaniswa kwazo, ukuklama nokusebenziseka kwazo, kanye nokukhetha okulungile nokushintshwa kwezimpawu esihlokweni.

Iyini i-drive oil seal?

I-Drive oil seal (i-cuff) - isici sokuvala amayunithi ahlukahlukene kanye nezinhlelo zezimoto;ingxenye eyinhlanganisela yendandatho eqinisekisa ukuvalwa kwamashafti, ama-bearings nezinye izingxenye ezijikelezayo ezindaweni lapho ziphuma khona emzimbeni weyunithi.

Kunoma iyiphi imoto, ugandaganda nezinye izinto ezisetshenziswayo kukhona amayunithi kanye nemishini, emzimbeni lapho kuphuma imishayo ejikelezayo - gearboxes, gearboxes, fan drives nabanye.Ngokuvamile kuba khona uwoyela noma okunye okokugcoba ngaphakathi kwala mayunithi, futhi imbobo ye-shaft ingabangela ukulahlekelwa kanye nokungcoliswa kwe-lubricant.Inkinga yokuvala ukuphuma kwama-shafts ajikelezayo ngaphandle kwezindlu zamayunithi ixazululwa ngosizo lwezakhi ezikhethekile zokuvala - izimpawu (ama-cuffs) we-drive.

I-drive oil seal yenza imisebenzi eminingana:

● Ukuvinjelwa kokuvuza kukawoyela kanye nokulahlekelwa okunye okokugcoba emzimbeni weyunithi noma umshini;

● Ukuvikelwa komshini emanzini, othulini nasezingcoleni ezinkulu;

● Ukuvikelwa kwe-lubricant ekungcolisweni yi-exhaust namanye amagesi.

Ukwephulwa kobuqotho noma ukulahlekelwa uphawu lwamafutha kuholela ekuvuzeni okuphawulekayo kwamafutha kanye nokungcoliswa kwawo, okungenzeka esikhathini esizayo esiseduze kungabangela ukuwohloka kweyunithi yonke.Ukuvimbela lokhu, insiza ephelelwe yisikhathi noma uphawu lwedrayivu olungalungile kufanele lushintshwe ngesikhathi esifanele.Ukuze ukhethe okulungile nokushintshwa kwezinto zokuvala uphawu, kuyadingeka ukuqonda izinhlobo ezikhona, ukuklama nokusebenza.

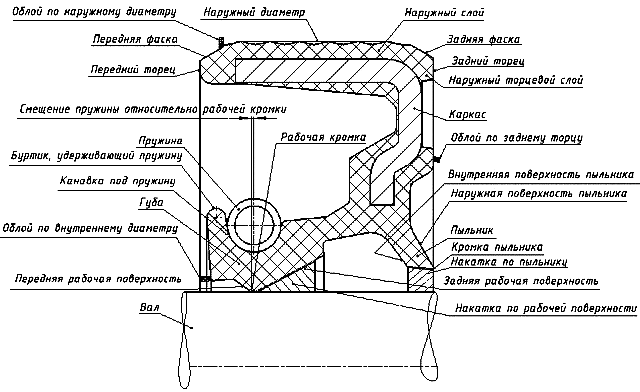

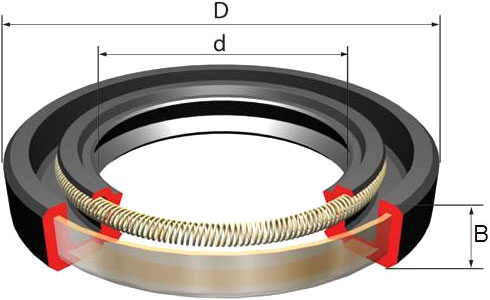

Idizayini ejwayelekile yophawu lokushayela

Izinhlobo, ukwakheka kanye nezici ze-drive seal

Zonke izimpawu zikawoyela zenziwe ngendlela yendandatho enephrofayili emise okwe-U, lapho kugqama khona izindawo ezintathu:

● Ingaphakathi noma elisebenzayo - liqukethe imiphetho yokusebenza, le ndawo yophawu lwamafutha ihlezi ku-shaft;

● Ingaphandle - ibushelelezi noma i-grooved, le ndawo yophawu lwamafutha ixhumene nomzimba weyunithi;

● End - ngokuvamile iphansi, le ndawo ihambisana nomzimba weyunithi.

I-cuff ifakwe esihlalweni emzimbeni weyunithi (ibhokisi lophawu lwamafutha) futhi ihlezi ku-shaft, ngenxa yomklamo, ukugoqa kwayo okuqinile emzimbeni kanye ne-shaft kuyaqinisekiswa, okufezekisa ukubekwa uphawu.

Izigxivizo zikawoyela zihlukaniswe zaba izinhlobo eziningana ngokuya ngokuba khona / ukungabikho kwezakhi ezahlukahlukene nezici zomsebenzi.

Okokuqala, izimpawu zikawoyela zihlukaniswa zibe izinhlobo ezimbili ngokuklama:

● Okungenasici;

● Ngohlaka oluqinisayo.

Idizayini ye-seal engaqinisiwe enentwasahlobo

Ukwakhiwa kanye nobukhulu obuyisisekelo bophawu lwamafutha aqinisiwe ngentwasahlobo

Izimpawu zamafutha zohlobo lokuqala zenziwa ngendlela yendandatho yokunwebeka yerabha yokwenziwa, endaweni engaphakathi lapho imiphetho yokusebenza yakhiwe khona.Njengendinganiso, amaphethelo amabili asebenzayo anikezwa ezimpawu zamafutha - ngaphambili nangemuva, kodwa inani labo lingafinyelela ezine.Ngaphakathi kwendandatho kukhona isiphethu sekhoyili esongile esigoqwe saba yindandatho, enikeza ukugoqa okuqinile kophawu lwamafutha ku-shaft.

Izimpawu zohlobo lwesibili ziyinkimbinkimbi kakhulu - ngaphakathi kwendandatho kukhona ifreyimu yokuqinisa insimbi yefomu elilodwa noma elinye.Imvamisa, ifreyimu inomugqa oqondile (ipuleti eligoqwe eringini) noma iphrofayili emise okwe-L, kepha kunezimpawu zamafutha ezinamafreyimu ephrofayili eyinkimbinkimbi.Uma kungenjalo, izingxenye eziqinisiwe zifana nalezo ezingaqinisiwe.

Izigxivizo zikawoyela ezinohlaka oluqinisayo zihlukaniswa zibe izinhlobo ezintathu zesakhiwo:

● Ngohlaka oluvaliwe;

● Ngefreyimu evezwe kancane;

● Ngohlaka olungenalutho.

Ekwakhiweni kohlobo lokuqala, ifreyimu itholakala ngokuphelele ngaphakathi kwendandatho yenjoloba yophawu lwamafutha, noma indandatho ihlanganisa ngokuphelele indawo yangaphandle yohlaka.Esimweni sesibili, indandatho ihlanganisa ukuphela kanye nengxenye yendawo yangaphandle yefreyimu, futhi esimweni sesithathu, ifreyimu icishe ivuleke ngokuphelele.Izigxivizo ezinohlaka oluqinisayo oluyingxenye futhi olungenalutho zifakwe ngokuqinile esihlalweni sazo, ngoba zihlezi emzimbeni wensimbi weyunithi enendandatho yensimbi.Nakuba izimpawu ezinjalo zinikeza uphawu olubi kakhulu, okwenza kudingeke ukusebenzisa ama-sealants noma izingxenye ezengeziwe.

Indandatho yokunwebeka yazo zonke izinhlobo zezimpawu zamafutha ingenziwa ngezinhlobo ezahlukahlukene zenjoloba yokwenziwa - i-acrylate, irabha ye-fluoro, i-butadiene-nitrile, i-silicone (i-organosilicon) nabanye.Lezi zinto zinokumelana okungalingani emazingeni okushisa aphezulu naphansi kanye nezinto zokugcoba, kodwa zinama-coefficients afanayo of friction kunsimbi namandla emishini.

Izigxivizo zeDrayivu zingaba nezinto ezihlukahlukene ezengeziwe:

● I-anther iyindawo encane engaphambili yeringi evimbela ukungcola okukhulu (amatshe, izintambo, ama-chips, njll.) ukuba kungene uphawu lukawoyela.I-anther ingacindezelwa ngokumelene ne-shaft ngenxa yokuqina kwayo noma ngosizo lwentwasahlobo eyengeziwe ehlanganisiwe;

● Ukugwaza kwendawo yangaphandle - ukugoba kwesimo esilula noma esiyinkimbinkimbi, okuthuthukisa ukulingana kophawu lwamafutha futhi kuvimbele ukuvuza kwamafutha ngesivinini esikhulu nalapho izinga lokushisa likhuphuka;

● I-Hydrodynamic knurling namanotshi endaweni engaphakathi (esebenzayo).Amanotshi anedeshi asetshenziswa nge-engeli ethile ku-eksisi yesivalo sikawoyela, okuvimbela ukuvuza kukawoyela ngesivinini esiphezulu se-shaft.Amanotshi angenziwa phezu kwayo yonke indawo engaphakathi, noma ngesimo samaringi ambalwa endaweni yokusebenza kanye nemiphetho yokusebenza.

Izigxivizo zamafutha zihlukaniswe ngamaqembu amabili ngendlela yokujikeleza kwe-shaft:

● Kumashafu anesiqondiso esingaguquki sokuzungezisa;

● Kumashafu azungezisayo.

Izigxivizo ngezinjongo ezihlukahlukene ziyehluka ngohlobo lokuguqa noma amanotshi endaweni yokusebenza.Ezimpawu zamafutha zama-shafts anesiqondiso esiqhubekayo sokujikeleza, i-knurling yenziwa ngendlela yokuqhafaza eqondiswe ohlangothini olulodwa, ngakho-ke izingxenye ezinjalo zinama-knurlings "kwesokudla" kanye "kwesokunxele" (notches).Kuma-omentum ahlehliswayo, inothi i-zigzag noma iyinkimbinkimbi ngomumo.

Umklamo we-Cassette gland

Okokugcina, izimpawu zokushayela ziyizinhlobo ezimbili mayelana nokuvikela:

● Okuvamile (okujwayelekile);

● Ikhasethi.

Izigxivizo zikawoyela ezivamile zinomklamo ochazwe ngenhla.Izigxivizo zekhasethi zenziwe ngendlela yezindandatho ezimbili ezifakwe enye kwenye (indandatho yangaphandle ihlezi emzimbeni weyunithi futhi ihlezi ku-shaft, indandatho yangaphakathi ihlezi ngaphandle futhi ingxenye ihlezi ku-shaft) - lo mklamo uyamelana. imithwalo ebalulekile yemishini futhi inikeza isivikelo esingcono ekungeneni kwezinto ezingcolile.Izigxivizo zekhasethi zisetshenziswa kumayunithi asebenza ezimeni zokwanda kothuli nokungcola.

Sengiphetha, siphawula ukuthi ezimotweni, ogandaganda nezinye izinto ezisetshenziswayo, izigxivizo zokushayela ezahlukahlukene zisetshenziselwa injongo yazo: ama-semi-axles amasondo, ama-gearbox shafts nama-gearbox, ama-fan drive shafts nabanye.Kodwa ingxenye enkulu yezingxenye itholakala ekudluliselweni, okuthole kuyo igama layo.

Indlela yokukhetha nokufaka esikhundleni se-drive oil seal

I-Drive seal ithola imithwalo ebalulekile, okuthi ngokuhamba kwesikhathi iholele ekugugekeni, ekulimaleni noma ekubhujisweni ngokuphelele kophawu.Lapho ukuvuza kwamafutha kubonakala, uphawu lwamafutha kufanele lushintshwe, ngaphandle kwalokho ukusetshenziswa kwamafutha kuzokwanda futhi ingozi yokungcoliswa kwayo izokwanda, okuvame ukwandisa ukuqina kokugqoka kwezingxenye zeyunithi.Futhi, izimpawu zikawoyela kufanele zishintshwe ekuthuthukisweni kwensiza - isikhathi sokushintsha ngokuvamile siboniswa umenzi weyunithi.

Yilezo zinhlobo kuphela namamodeli wezimpawu zikawoyela ezifakwe ngaphambilini futhi zatuswa umenzi womshini (okunqunywa inombolo yengxenye kukhathalogi yasekuqaleni) okufanele zisetshenziselwe ukumiselela.Kwezinye izimo, kuvunyelwe ukuphendukela ekushintsheni, kodwa lokhu kufanele kwenziwe ngokuqapha futhi kucatshangelwe izici eziyingqayizivele ze-cuffs ngezinhloso ezihlukahlukene.Isibonelo, izimpawu zama-semi-axles ama-axle okushayela kufanele zibe ne-notch ehlehliswayo (i-knurling), ngaphandle kwalokho ngemva kokufakwa kwazo kuzoba nokuvuza kwamafutha ezindleleni ezithile zokushayela noma ukuvuza okuqhubekayo ngenxa yokusebenza okungalungile kophawu.Ngakolunye uhlangothi, akunangqondo ukubeka i-cuff ebuyela emuva ku-fan, njengoba i-shaft evaliwe ihlale ijikeleza ohlangothini olulodwa.

Ukushintshwa kwama-drive seal kufanele kwenziwe ngokuhambisana nemiyalelo yokulungisa nokugcinwa kwemoto.Lo msebenzi ungadinga ukuhlukaniswa okuphawulekayo kweyunithi elungisiwe, ngakho-ke kungcono ukuthembela kochwepheshe.Lapho ufaka uphawu ngokwakho, kuyadingeka ukunamathela ngokuqinile ezincomo ezinikezwe emiyalweni, ngaphandle kwalokho kunengozi enkulu yokulimaza ingxenye noma ukuyifaka ngokungalungile.Ukufaka i-cuff endala kungenziwa nge-screwdriver evamile noma enye into ekhonjiwe, kodwa lokhu kufanele kwenziwe ngokucophelela ukuze kungalimazi indawo yecala kanye ne-shaft.Ukufakwa uphawu olusha kungcono ukwenza ngosizo lwe-mandrel ekhethekile eqinisekisa ukucwiliswa komfaniswano we-oil seal ebhokisini lophawu lwamafutha.Ngaphambi kokufakwa, i-cuff igcotshwa nge-lubricant.Ezimweni lapho kusetshenziswa uphawu olunefreyimu yokuqinisa engenalutho noma evezwe kancane, kuyadingeka ukuphatha indawo yokuxhumana nohlaka ngomzimba weyunithi nge-sealant.Ngemuva kokwenza umsebenzi, kuyadingeka ukwengeza amafutha ku-crankcase yeyunithi.

Ngokukhethwa okulungile nokushintshwa kwe-drive seal, iyunithi izokwenza imisebenzi yayo ngokuthembekile, umsebenzi wayo ngeke uphazanyiswe ukuvuza nokungcoliswa kwamafutha kunoma yiziphi izimo zokusebenza.

Isikhathi sokuthumela: May-06-2023