Kumabhuleki amasondo ezimoto eziningi zesimanje kukhona ingxenye ehlinzeka ngokulungiswa nokuvikela izingxenye - i-brake shield.Konke mayelana ne-brake shield, imisebenzi yayo eyinhloko kanye nomklamo, kanye nokugcinwa nokulungiswa kwale ngxenye, ungafunda kulesi sihloko.

Yini i-brake shield?

I-Brake shield (isihlangu, isembozo sokuzivikela, isikrini sokuzivikela) - ingxenye yamabhuleki amasondo ezimoto ezinamasondo;Ingxenye yensimbi esesimweni sesihlangu esiyindilinga noma esiyi-semicircular esibamba izingxenye ezithile ze-brake mechanism futhi izivikele ekungcoleni, ekulimaleni kwemishini kanye namathonya amabi emvelo.

Zonke izimoto zesimanje ezinamasondo zifakwe amabhuleki ohlobo lwe-friction abekwe ngqo ku-asi yamasondo.Ngokwesiko, amabhuleki amasondo anezingxenye ezimbili: ezinyakazayo, ezixhunywe kwihabhu lamasondo, futhi azigxilile, ezihlotshaniswa nequpha lokuqondisa (emasondo angaphambili), izingxenye zokulengiswa noma i-axle beam flange (emasondo angemuva nangasemuva).Ingxenye enyakazayo yomshini ihlanganisa isigubhu sebhuleki noma idiski exhunywe ngokuqinile kuhabhu nediski yesondo.Engxenyeni engaguquki kukhona ama-brake pads kanye ne-drive yawo (amasilinda, i-caliper enamasilinda kuma-disc brakes), kanye nenani lezingxenye ezisizayo (i-parking brake drive, izinhlobo ezahlukene zezinzwa, izakhi zokubuyisela nezinye).Izingxenye ezilungisiwe zitholakala entweni ekhethekile - isihlangu (noma i-casing) yebhuleki.

Isihlangu sitholakala ngaphakathi kwe-wheel brake mechanism, sinamathiselwe ngqo ku-knuckle yokuqondisa, i-bridge beam flange noma izingxenye zokumiswa, imisebenzi eminingana inikezwe yona:

● Umsebenzi wesici samandla ukubamba izingxenye ezingashintshi zendlela yesondo, ukuqinisekisa ukuma kwazo ngendlela efanele kuzo zonke izindlela zokusebenza zamabhuleki;

● Umsebenzi wesici somzimba ukuvikela izingxenye zemishini yamabhuleki ekungeneni kokungcola okukhulu kwemishini nezinto zangaphandle, kanye nokuvikelwa kwazo ekulimaleni kwemishini ngenxa yokuxhumana nezinye izingxenye zesakhiwo semoto nezinto zangaphandle;

● Imisebenzi yesevisi - enikeza ukufinyelela ezintweni eziyinhloko zokulungisa zendlela yokwenza ukunakekelwa nokuhlola okubonakalayo kwamabhuleki.

I-brake shield ayiyona ingxenye ebalulekile ekusebenzeni kwamabhuleki, noma kunjalo, uma le ngxenye iphuka noma ingekho, amabhuleki angaphansi kokuguga okukhulu futhi angahluleka ngesikhathi esifushane.Ngakho-ke, uma kukhona izinkinga ngesihlangu, kufanele kushintshwe, futhi ukuze kwenziwe ukulungiswa okulungile, kuyadingeka ukuqonda ukuklama nezici zalezi zingxenye.

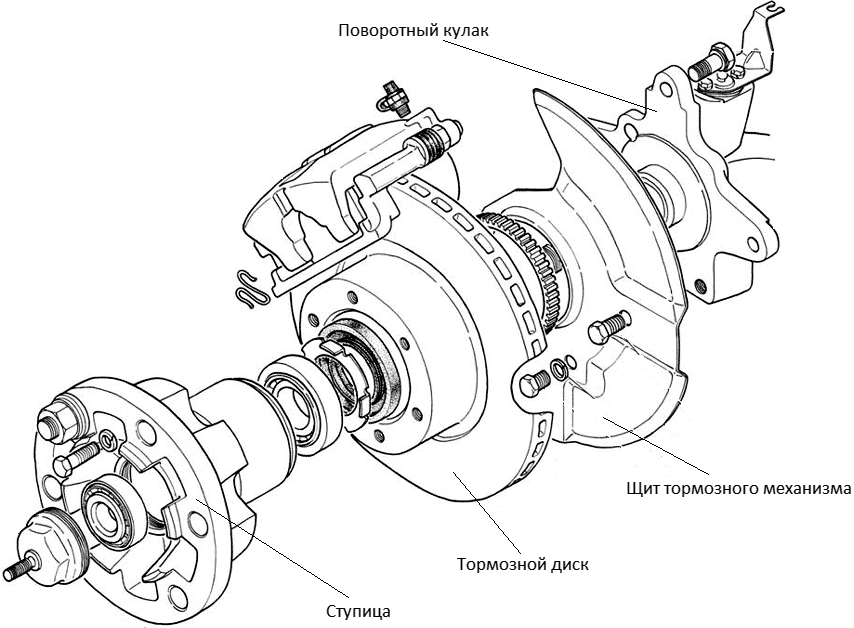

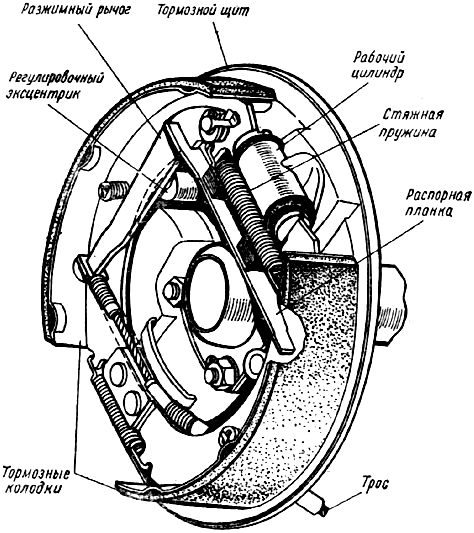

Idivayisi ye-disc brake mechanism kanye nendawo yesihlangu kuyoIdizayini ye-drum brake mechanism kanye nendawo yesihlangu kuyo

Izinhlobo kanye nomklamo wama-brake shields

Ezimotweni nasezimotweni ezinamasondo ahlukahlukene, kusetshenziswa izihlangu zamabhuleki ezifana ngokuyisisekelo ekwakhiweni: lena ingxenye yensimbi enesitembu esesimweni somjikelezo noma i-semicircle, lapho kwenziwa khona izimbobo ezahlukahlukene, ama-niches kanye nezinto ezisizayo zokufakwa kwezakhi zamabhuleki. .Ngokuvamile, isihlangu simbozwe ngopende omnyama, ovikela ingxenye ekugqwaleni.Imininingwane ehlukahlukene ingatholakala kuhawu:

● Imbobo emaphakathi yehabhu lamasondo noma i-axle shaft;

● Izimbobo ezifakwayo - zokufaka isihlangu engxenyeni engashintshi yokumiswa;

● Ukubuka amafasitela - ukufinyelela ezingxenyeni zomshini wamabhuleki ngaphandle kokudiliza isondo nesihlangu ngokwaso;

● Izimbobo zokubopha izingxenye zendlela yamabhuleki;

● Amahinge nabakaki bokulungisa iziphethu nezinye izingxenye zemishini;

● Izihlahla ezicindezelwe zokufaka izintambo, ukufaka izimbazo zamalever, izinzwa nezinye izingxenye;

● Amapulatifomu nezitobhi zokubeka maphakathi nendawo nokuma kahle kwezingxenye.

Ngesikhathi esifanayo, kunezinhlobo ezimbili zama-brake shields mayelana nokusetshenziswa: i-disc kanye namabhuleki ezigubhu.Banomklamo ohlukile, obuye uncike endaweni - emasondweni angaphambili, emasondweni angemuva noma emasondweni e-axle edonsa ngemuva.

Ngokwesakhiwo, amasondo amasondo angaphambili nangemuva ezimoto ezinama-disc brakes yiwona alula.Eqinisweni, i-casing yensimbi enesitembu nje, efakwe kwi-knuckle yokuqondisa (ngaphansi kwehabhu) noma ezintweni ezimisiwe ezimisiwe, futhi ethatha imisebenzi yokuvikela kuphela.Njengomthetho, imbobo ephakathi kuphela, inqwaba yezimbobo ezikhulayo kanye nokusika okucatshangelwayo kwengxenye ye-caliper ephuma ngaphakathi kwesondo kwenziwa kule ngxenye.

Okuyinkimbinkimbi kakhulu izihlangu zawo wonke amasondo anamabhuleki ezigubhu.Yonke imishini itholakala kuma-casings anjalo - i-cylinder ye-brake (noma amasilinda), ama-pads, izingxenye ze-pad drive, iziphethu, izakhi zokupaka i-brake drive, izakhi zokulungisa nezinye.Isihlangu sinembobo emaphakathi kanye nezimbobo ezifakwayo, ngosizo lapho yonke inhlangano ifakwe ku-flange ye-axle ye-drive noma izakhi zokumiswa.Lolu hlobo lwengxenye lunezidingo ezingathi sína zamandla nokuqina, njengoba ludlala indima ebalulekile ekusebenzeni kwawo wonke umshini wamabhuleki.Ngakho-ke, yenziwe ngensimbi enamandla futhi eqinile, ngokuvamile inama-stiffeners (okuhlanganisa ibhodi le-annular elizungeze umjikelezo wesihlangu) kanye nezakhi zokuqinisa ezisizayo.

Sengiphetha, kufanele kuqashelwe ukuthi izihlangu zamabhuleki ziqinile futhi ziyinhlanganisela.Esimweni sokuqala, yingxenye eyodwa enesitembu, okwesibili - ingxenye esele yezingxenye ezimbili (amasongo angamahhafu).Ngokuvamile, izingxenye zisetshenziselwa amaloli, zenza kube lula ukufakwa, ukugcinwa nokulungiswa kwamabhuleki, futhi uma kwenzeka umonakalo, kwanele ukufaka ingxenye eyodwa kuphela, okunciphisa izindleko.

Izinkinga zokunakekela, ukukhethwa kanye nokushintshwa kwezihlangu zamabhuleki

I-brake shield ayidingi ukunakekelwa okukhethekile ngesikhathi sokusebenza kwemoto - kufanele ihlolwe ekugcinweni ngakunye kwamabhuleki, futhi, uma kunesidingo, kuhlanzwe ukungcola.Uma isihlangu sonakalisiwe noma sikhubazekile (ikakhulukazi i-drum brake shield), kunconywa ukushintshwa.Ukuze kulungiswe, kuyadingeka ukusebenzisa ingxenye yohlobo olufanayo nenombolo yekhathalogi eyafakwa ngaphambili.Ngaphezu kwalokho, kufanele kukhunjulwe ukuthi izihlangu azikho kuphela ngaphambili nangemuva, kodwa futhi kwesokudla nakwesokunxele.

Ukushintshwa kwengxenye kufanele kwenziwe ngokuhambisana nemiyalelo yokulungiswa nokugcinwa kwale moto ethile.Ngokuvamile, lo msebenzi ufinyelela kulokhu okulandelayo:

1.Phakamisa imoto ngojeke (ngemuva kokuyibhuleka nokuqinisekisa ukuthi ayinyakazi);

2.Susa isondo;

3.Khipha isigubhu se-brake noma i-disc nge-caliper (lokhu kungase kudinge inani lemisebenzi yokusiza - ukuphula isigubhu esivela esihlalweni ngokufaka izikulufu ezikulungeni, nabanye);

4.Dismantle ihabhu lamasondo (kumabhuleki ediski, ihabhu livame ukususwa kanye nesihlangu);

5.Dismantle isihlangu se-brake nazo zonke izingxenye ezifakwe kuso (lokhu kungase kudinge ukhiye okhethekile, futhi ukufinyelela kuma-fasteners kuvame ukuvulwa kuphela ngezimbobo ezikhethekile kuhabhu).

I-Brake shield enezingxenye zamabhuleki ezifakiwe

Uma imoto ene-disc brakes ilungiswa, khona-ke wonke umsebenzi uyancishiswa esikhundleni esilula se-casing.Ngemuva kwalokho, yonke i-node ihlanganiswa ngokulandelana okuphambene.Uma umsebenzi wenziwa emotweni enamabhuleki esigubhu, khona-ke ngemuva kokudiliza isihlangu, kuyadingeka ukususa izingxenye zamabhuleki kuso, uzifake esihlanguni esisha, bese uzihlanganisa kabusha.Ngemuva kokulungiswa, kuyadingeka ukwenza yonke imisebenzi yokulawula ukuthwala ihabhu (uma kuhlinzekiwe), kanye nokugcina nokulungisa uhlelo lwebhuleki yemoto.

Ungabona ukuthi esikhundleni se-brake shield kubonakala kulula - ngenxa yalokhu kufanele uhlakaze ngokuphelele isondo kanye nezinqubo ezikuyo.Ngakho-ke, kuyadingeka ukukhetha ingxenye efanele futhi wenze ukulungisa ngokuhambisana nazo zonke izincomo ze-automaker.Uma iphutha lenziwa, kuzothatha isikhathi esiningi nomzamo ukulilungisa.Umphumela onokwethenjelwa ungafinyelelwa kuphela ngokuthengwa okulungile kwezingxenye ezisele kanye nendlela eqondile yokulungisa umsebenzi.

Isikhathi sokuthumela: Jul-12-2023