Imoto ngayinye kufanele ifakwe i-braking system, ama-actuator awo angama-brake pads axhumene nesigubhu samabhuleki noma idiski.Ingxenye eyinhloko yama-pads yi-friction linings.Funda konke mayelana nalezi zingxenye, izinhlobo zazo, ukuklama kanye nokukhetha okulungile esihlokweni.

Iyini i-brake pad line?

I-brake pad lining (i-friction lining) iyingxenye ye-actuator yamabhuleki ezimoto, okuqinisekisa ukwakhiwa kwe-torque yokubhuleka ngenxa yamandla aphikisanayo.

I-friction lining iyingxenye eyinhloko ye-brake pad, ixhumene ngqo nesigubhu sebhuleki noma i-disc lapho ibhuleka imoto.Ngenxa yamandla okungqubuzana avela ekuthintaneni nesigubhu / idiski, ulwelwesi lumunca amandla e-kinetic emoto, luyiguqulele ekushiseni futhi lunikeze ukwehla kwejubane noma ukuma okuphelele.Ama-linings ane-coefficient eyandayo yokungqubuzana ngensimbi eyinsimbi nensimbi (okwenziwa kuyo izigubhu zamabhuleki nama-disc), futhi ngesikhathi esifanayo abe nokumelana okuphezulu kokugqoka nokuvimbela ukuguga ngokweqile kwesigubhu / idiski.

Namuhla, kunezinhlobonhlobo eziningi ze-brake pad linings, futhi ukuze ukhethe kahle lezi zingxenye, kuyadingeka ukuqonda ukuhlukaniswa nokuklama kwazo.

Izinhlobo kanye nomklamo we-brake pad linings

I-Friction linings yama-brake pads ingahlukaniswa ngamaqembu ngokusho kwenhloso, ukuklama nokucushwa, kanye nokwakheka okuvela kuyo.

Ngokwenhloso, ama-pads ahlukaniswe izinhlobo ezimbili:

• Ngamabhuleki ezigubhu;

• Ngamabhuleki ediski.

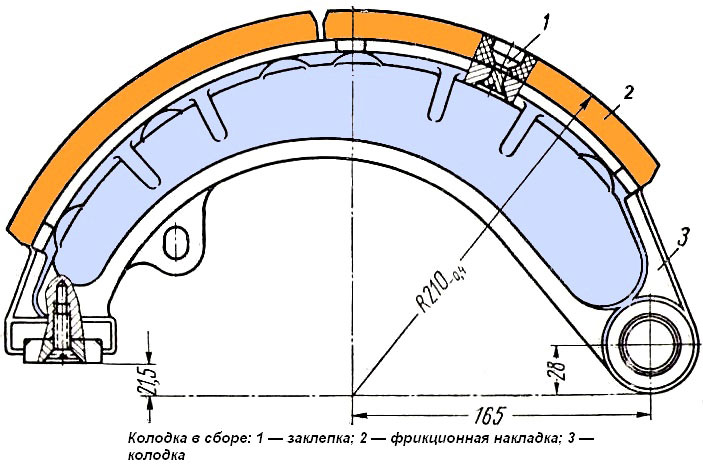

Ama-drum brake pads ayipuleti le-arcuate eline-radius yangaphandle ehambisana ne-radius engaphakathi yesigubhu.Uma ubhuleka, ama-lining ahlala endaweni engaphakathi yesigubhu, enciphisa isivinini semoto.Njengomthetho, ama-drum brake friction linings anendawo enkulu yokusebenza.I-wheel brake mechanism ngayinye ifakwe ama-lining amabili abhekene nomunye, okuqinisekisa ukusatshalaliswa okulinganayo kwamandla.

Ama-brake linings angamapuleti ayisicaba e-crescent noma ezinye izimo ezinikeza indawo enkulu yokuxhumana ne-brake disc.I-wheel brake mechanism ngayinye isebenzisa amaphedi amabili, lapho idiski iboshiwe khona ngesikhathi sokubhuleka.

Futhi, i-brake pad linings ihlukaniswe ngamaqembu amabili ngokuya ngendawo yokufaka:

• Ngamabhuleki amasondo - ngaphambili, ngemuva kanye nendawo yonke;

• Okokusebenza kwamabhuleki okupaka amaloli (ngesigubhu ku-propeller shaft).

Ngokwesakhiwo, ama-friction linings angamapuleti abunjwe kusuka ekwakhiweni kwe-polymer enokwakheka okuyinkimbinkimbi.Ukubunjwa kuhlanganisa izingxenye ezihlukahlukene - uhlaka-ukwakheka, ukugcwalisa, ukulahla ukushisa, ama-binders nabanye.Ngasikhathi sinye, zonke izinto okwenziwa kuzo ama-linings zingahlukaniswa ngamaqembu amabili amakhulu:

•I-Asbestos;

• I-asbestos-free.

Isisekelo se-asbestos linings, njengoba kulula ukuyiqonda, imicu ye-asbestos (namuhla iyi-asbestos ye-chrysotile ephephile), esebenza njengohlaka lwepuleti olubamba zonke ezinye izingxenye.Amaphedi anjalo athambile, kodwa ngesikhathi esifanayo ane-coefficient ephezulu yokungqubuzana, avimbela ukugqoka ngokweqile kwesigubhu / idiski futhi abe nezinga lomsindo elincishisiwe.Emikhiqizweni engenayo i-asbestos, i-polymer ehlukahlukene noma imicu yamaminerali idlala indima yohlaka lokubunjwa, ukunqwabelanisa okunjalo kuhambisana nezindinganiso zemvelo, kodwa kubiza kakhulu futhi kwezinye izimo kunezici zokusebenza ezimbi kakhulu (ziqinile, zivame ukuba nomsindo, njll. .).Ngakho-ke, namuhla izingqimba ze-asbestos friction zisasetshenziswa kabanzi.

Izinto ezihlukahlukene ze-polymeric zisetshenziswa njengezigcwalisi ekwenziweni kokumbondelana, ama-polymers, ama-resin, ama-rubber, njll. Ukwengeza, izitsha zobumba, ama-shavings ensimbi (enziwe ngethusi noma ezinye izinsimbi ezithambile) ukuze kukhishwe ukushisa okungcono, nezinye izingxenye zingase zibe khona ekubunjweni. .Cishe wonke umkhiqizi usebenzisa izindlela zakhe zokupheka (ngezinye izikhathi eziyingqayizivele), ngakho ukwakheka kwama-friction linings kungahluka kakhulu.

Ama-friction linings akhiqizwa kusetshenziswa ubuchwepheshe obubili obuyinhloko:

• Ukucindezela okubandayo;

• Ukucindezela okushisayo.

Esimweni sokuqala, ama-linings akhiwa kusukela kungxube eqediwe ekubunjweni okukhethekile ngaphandle kokushisa okwengeziwe.Kodwa-ke, abakhiqizi abaningi ngaphezu kwalokho basebenzisa ukwelashwa okushisa kwemikhiqizo ngemuva kokubunjwa.Esimweni sesibili, ingxube icindezelwe ekubunjweni okushisayo (kagesi).Njengomthetho, ngokucindezela okubandayo, ama-linings ashibhile, kodwa ahlala isikhathi eside atholakala, ngokucindezela okushisayo, imikhiqizo isezingeni eliphakeme, kodwa futhi ibiza kakhulu.

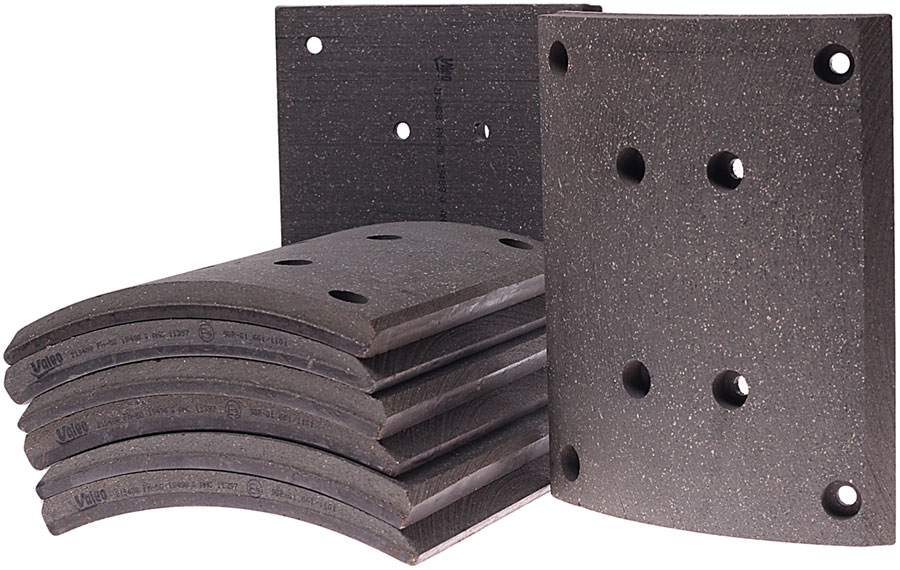

Kungakhathaliseki ukuthi iyiphi indlela yokukhiqiza nokubunjwa, ngemva kokukhiqiza, ama-linings ayapholishwa futhi angaphansi kokunye ukucubungula okwengeziwe.Ama-friction linings athengiswa ngezindlela ezihlukahlukene:

• Imbondela ngaphandle kwezimbobo ezifakwayo nezinsimbi;

• Imbondela enezimbobo ezimboziwe;

• Imbondela enezimbobo kanye nesethi yezinsimbi;

• Gcwalisa ama-brake pads - ama-linings agxunyekwe esisekelweni.

I-Friction linings yama-brake pads angenazimbobo ayizingxenye zomhlaba wonke ezingalungiswa kuma-brake pads ezimoto ezihlukahlukene, ezinobukhulu obufanele kanye ne-radius.Izimbobo ezinezimbobo zifanelekile kumamodeli athile emoto, kungenzeka ukuzifaka kumaphedi ngohlelo oluhlukile lwezimbobo kuphela ngemuva kokubhoboza okwengeziwe, noma akunakwenzeka ngokuphelele.Imbondela egcwele ngezixhumi kusiza inqubo yokufaka futhi isize ukuqinisekisa umphumela wekhwalithi ephezulu kakhulu.

Ama-brake pads aphelele asewuhlobo oluhlukile lwezingxenye eziyisipele, asetshenziswa ekulungiseni amabhuleki ediski, izindlela zokudonsa izigubhu ezinamaphedi anamathiselwe kuma-pads, noma izigubhu eziguge kabi.Emalolini, izingxenye ezinjalo azivamile ukusetshenziswa.

Ama-friction linings afakwe kuma-brake pads anama-rivets (aqinile futhi angenalutho) noma ku-glue.Ama-rivets asetshenziswa kumabhuleki ezigubhu, iglue isetshenziswa kakhulu kuma-disc brake pads.Ukusetshenziswa kwama-rivets kunikeza amandla okushintsha ama-linings njengoba eguga.Ukuvimbela ukulimala kwesigubhu se-brake noma i-disc, ama-rivets enziwe ngezinsimbi ezithambile - i-aluminium nama-alloys ayo, ithusi, ithusi.

Izinzwa zokugqoka zikagesi nezemishini zingafakwa kuma-lining pad amabhuleki esimanje.Inzwa yomshini ipuleti emzimbeni we-lining, okuthi, lapho ingxenye iguga, iqale ukugudla isigubhu noma i-disc, yenza umsindo wesici.Inzwa ye-elekthronikhi nayo ifihliwe emzimbeni we-lining, uma igqokile, isifunda sivaliwe (ngediski noma isigubhu) futhi inkomba ehambisanayo ikhanyisa kudeshibhodi.

Ukukhetha okulungile, ukushintshwa kanye nokusebenza kwama-brake pad linings

Ama-friction linings angaphansi kokugqoka ngesikhathi sokusebenza, ukushuba kwawo kuncipha kancane kancane, okuholela ekwehleni kokuthembeka kwamabhuleki.Njengomthetho, umugqa owodwa usebenza amakhilomitha ayizinkulungwane ezingu-15-30, emva kwalokho kufanele ushintshwe.Ezimweni ezinzima zokusebenza (ukwanda kothuli, ukunyakaza emanzini nokungcola, lapho usebenza ngaphansi kwemithwalo ephezulu), ukushintshwa kwama-linings kufanele kwenziwe kaningi.I-linings kufanele ishintshwe uma igqokwe kuze kube buncane obuvunyelwe ukushuba - ngokuvamile okungenani 2-3 mm.

Ukuze kushintshwe, kuyadingeka ukusebenzisa ama-friction linings anezilinganiso ezifanele imoto ethile - ububanzi, ubude nobukhulu (yonke imingcele edingekayo ivame ukuboniswa kuma-linings).Kulokhu kuphela, i-lining izocindezelwa ngokugcwele isigubhu noma idiski futhi kuzokwakhiwa amandla anele okubhuleka.Ukufaka i-pad ku-block, ungasebenzisa kuphela ama-rivets enziwe ngezinsimbi ezithambile, kungcono ukunikeza okuthandayo kuma-fasteners kukhithi.Ama-rivets kufanele agqitshwe emzimbeni wezintambo ukuze avimbele ukuthi angakhuhli esigubhu, ngaphandle kwalokho izingxenye zizoguga kakhulu futhi zingase zehluleke.

Kudingekile ukushintsha ama-linings kuma-brake pads ngamasethi aphelele, noma, ezimweni ezimbi kakhulu, kokubili esondweni elifanayo - lena ukuphela kwendlela yokuqinisekisa ukusebenza okujwayelekile kwezinqubo zokubopha.Kuyadingeka ukufeza ukushintshwa ngokuhambisana ngokugcwele nemiyalelo yokulungisa nokugcinwa kwemoto ethile, ngaphandle kwalokho kunamathuba amaningi okuwohloka kwamabhuleki.

Lapho usebenzisa imoto, kufanele ugweme ukushisa ngokweqile kwama-linings, kanye nokumanzisa nokungcola kwawo - konke lokhu kunciphisa insiza yabo futhi kwandisa amathuba okuphuka.Lapho ushayela emanzini, ama-linings adinga ukumiswa (ukusheshisa izikhathi eziningana bese ucindezela i-pedal ye-brake), ngokwehla okude, kunconywa ukuthi uphendukele ekubhulekini kwe-injini, njll. Ngokusebenza kahle nokushintshwa okufika ngesikhathi kwama-linings, amabhuleki emoto. izosebenza ngokwethembeka nangokuphepha.

Isikhathi sokuthumela: Aug-22-2023