Ezinjini eziningi ezivuthayo zangaphakathi, indlela yokusabalalisa igesi iqukethe izingxenye eziqinisekisa ukudluliselwa kwamandla kusuka ku-camshaft kuya kuma-valve - ama-pusher.Funda konke mayelana nama-valve tappets, izinhlobo zawo, ukwakheka kanye nezici zokusebenza, kanye nokukhetha nokushintshwa kwawo, kulesi sihloko.

Iyini i-valve tappet?

I-valve tappet iyingxenye yendlela yokusabalalisa igesi yenjini evuthayo yangaphakathi yepiston;idivayisi yokulandelela isikhathi, edlulisela amandla e-axial ukusuka ku-camshaft kuya ku-valve ngokuqondile noma ngokusebenzisa izakhi ezisizayo (induku, ingalo ye-rocker).

Indlela yokusabalalisa igesi yanoma iyiphi injini evuthayo yangaphakathi ngokuvamile isekelwe ezingxenyeni ezintathu eziyinhloko: i-camshaft, ezungeza ngokuhambisanayo (kodwa ngesigamu sesivinini se-angular) ne-crankshaft, ama-valve kanye nokushayela kwawo.I-actuator ye-valve mechanism iqapha indawo ye-camshaft futhi iqinisekisa ukudluliswa kwamandla ukusuka kuyo kuya kuma-valve.Izingxenye ezihlukahlukene zingasetshenziswa njengedrayivu: izinduku, izingalo ze-rocker ezinezinduku nangaphandle, nabanye.Esikhathini esiningi, izingxenye ezengeziwe ziyasetshenziswa - ama-pusher.

Ama-pushers wesikhathi enza imisebenzi eminingana:

● Asebenza njengesixhumanisi phakathi kwekhamera ye-camshaft nezinye izingxenye ze-valve drive;

● Ukuhlinzeka ngokudluliswa kwamandla okuthembekile kusuka kukhamera ye-camshaft kuya ku-valve ngayinye;

● Ukusabalalisa ngokulinganayo imithwalo evela ekujikelezweni kwe-camshaft kanye nokusebenza kwesikhathi;

● Ukwandisa impilo yesevisi yezingxenye zesikhathi futhi kube lula ukugcinwa kwayo;

● Abaphushi bezinhlobo ezithile - banikeza izikhala ezidingekayo zokushisa phakathi kwezingxenye zesikhathi kanye / noma basize inqubo yokulungiswa kwazo.

I-valve tappet iyingxenye ebalulekile yesikhathi, uma kwenzeka ukungasebenzi kahle lapho ukusebenza kwenjini konakala kakhulu.Uma kwenzeka ukuphuka, i-pusher kufanele ishintshwe, futhi ukuze ukhethe kahle ingxenye entsha, kuyadingeka ukuqonda izinhlobo ezikhona kanye nemiklamo yama-pusher.

Izinhlobo kanye nomklamo of ompompi valve

Ngokusho komklamo kanye nesimiso sokusebenza, ama-pusher ahlukaniswe ngezinhlobo eziningana:

● I-Belleville;

● I-Cylindrical (piston);

● Irola;

● I-Hydraulic.

I-pusher ngayinye inezici zayo zokuklama kanye nezinhlelo zokusebenza.

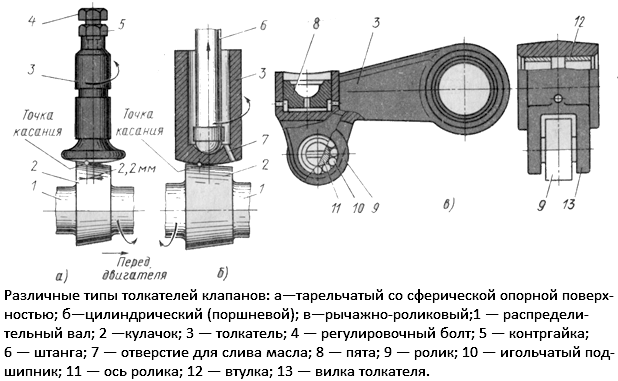

Izinhlobo ezahlukene zama-valve tappets

Amapayipi we-valve we-poppet

Ngokuvamile, i-pusher enjalo iqukethe induku kanye ne-disc base, lapho ihlezi khona kukhamera ye-camshaft.Ekupheleni kwenduku kukhona intambo yokufaka i-bolt yokulungisa nge-locknut, lapho kulungiswa khona izikhala ezishisayo.Ingxenye esekelayo ye-pusher ingaphansi kokwelashwa kokushisa (i-carburization) ukuze kwandiswe ukumelana kwayo nokugqoka.

Ngokwesimo sengxenye esekelayo (ipuleti), lawa ma-pusher ahlukaniswe ngamaqembu amabili:

● Ngokusekelwa okuyisicaba;

● Ngokusekelwa okuyindilinga.

Ama-Pushers ohlobo lokuqala asebenza ngokuhambisana ne-camshaft enamakhamera anendawo yokusebenza eyi-cylindrical.Ama-Pushers ohlobo lwesibili asetshenziswa ngama-camshaft anamakhamera angama-conical (enendawo yokusebenza ene-beveled) - ngenxa yalo mklamo, i-pusher ijikeleza ngesikhathi sokusebenza kwenjini, okuqinisekisa ukugqokwa kwayo okufanayo.

Ama-disc tappets awasasetshenziswa manje, afakwe ezinjinini ezinama-valve aphansi noma asemaceleni abhangqwe nezinduku noma ezingenazo.

Ama-valve angama-cylindrical (piston).

Kunezinhlobo ezintathu eziyinhloko zama-pusher zalolu hlobo:

● I-cylindrical hollow;

● Izibuko ngaphansi kwe-barbell;

● Izibuko ngaphansi kwevalvu.

Esimweni sokuqala, i-pusher yenziwe ngesimo se-cylinder evaliwe, okuthi, ukuze kube lula ukuklama, inemigodi namafasitela ngaphakathi.Ngakolunye uhlangothi kukhona intambo yebhawodi yokulungisa ene-locknut.Ama-pusher anjalo awavamile ukusetshenziswa namuhla, njengoba emakhulu futhi andisa izilinganiso zaso sonke isikhathi.

Esimweni sesibili, i-pusher yenziwe ngendlela yengilazi yobubanzi obuncane, ngaphakathi lapho i-recess (isithende) yenziwe ukufakwa kwenduku ye-pusher.Amafasitela angenziwa ezindongeni zengxenye ukuze kube lula futhi ukugcoba okuvamile.Abaphusha balolu hlobo basatholakala kumayunithi kagesi amadala ane-camshaft ephansi.

Esimweni sesithathu, i-pusher yenziwe ngendlela yengilazi yobubanzi obukhulu, ngaphakathi lapho iphuzu lokuxhumana lenziwa ukuze kugcizelelwe ekugcineni kwe-valve stem.Ngokuvamile, i-pusher inodonga oluncane, indawo yayo engezansi nendawo yokuxhumana iphathwa ngokushisa (iqinile noma i-carburized).Izingxenye ezinjalo zisetshenziswa kabanzi, zifakwe ezinjinini ezine-camshaft ephezulu kanye ne-valve drive eqondile.

Uhlobo lwe-cylindrical pusher ye-valve i-pusher ene-washer yokulungisa efakwe phansi (ikhamera ye-camshaft ihlezi ngokumelene nayo).I-washer ingaba nobukhulu obuhlukile, ukushintshwa kwayo kwenziwa ngokulungisa izikhala ezishisayo.

Ama-valve ama-roller

Kunezinhlobo ezimbili eziyinhloko zama-pusher zalolu hlobo:

● Phelisa;

● I-Lever.

Esimweni sokuqala, i-pusher yenziwe ngendlela ye-cylindrical rod, engxenyeni engezansi lapho i-roller yensimbi ifakwe khona ngenaliti enenaliti, futhi i-recess (isithende) yenduku inikezwa ekupheleni okuphezulu.Esimweni sesibili, ingxenye yenziwe ngendlela ye-lever ngokusekelwa okukodwa, ehlombe lapho i-roller ifakwe khona futhi kukhona ikhefu lenduku.

Amadivayisi alolu hlobo asetshenziswa kakhulu ezinjinini ezine-camshaft ephansi, azitholakali kumayunithi wamandla amasha.

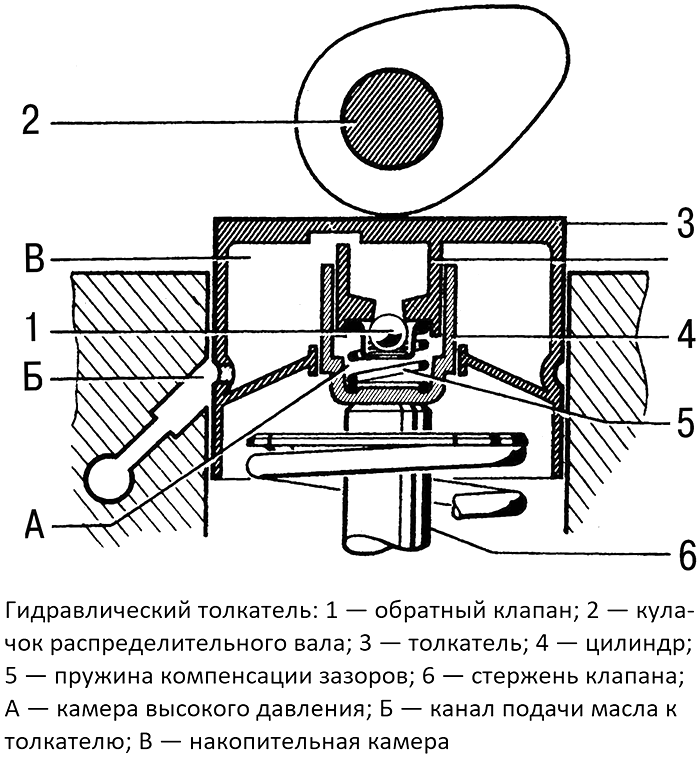

Amapayipi e-hydraulic valve

Ama-hydraulic pushers (ama-hydraulic lifters) ayisixazululo sesimanje kakhulu esisetshenziswa ezinjinini eziningi.Ama-Pushers alolu hlobo anomshini we-hydraulic eyakhelwe ngaphakathi wokulungisa izikhala ezishisayo, ezikhetha ngokuzenzakalelayo izikhala futhi ziqinisekise ukusebenza okuvamile kwemoto.

Isisekelo somklamo we-pusher ngumzimba (owenza ngesikhathi esifanayo imisebenzi ye-plunger), eyenziwe ngendlela yengilazi ebanzi.Ngaphakathi emzimbeni kunesilinda esinyakazayo esine-valve yokuhlola ehlukanisa isilinda sibe imigodi emibili.Ngaphandle kwendawo yokuphakamisa i-hydraulic, i-groove eyindilinga yenziwa enezimbobo zokuphakela uwoyela kusilinda kusuka ohlelweni lokugcotshwa kwenjini.I-pusher ifakwe ekugcineni kwesiqu se-valve, kuyilapho i-groove emzimbeni wayo ihambisana nomgudu wamafutha ekhanda le-block.

I-hydraulic pusher isebenza kanje.Ngaleso sikhathi lapho i-camshaft cam ingena ku-pusher, isilinda sithola ingcindezi evela ku-valve futhi ikhuphukele phezulu, i-valve yokuhlola ivala futhi ikhiye uwoyela otholakala ngaphakathi kwesilinda - sonke isakhiwo sihamba sisonke, siqinisekisa ukuvulwa kwe-valve. .Ngesikhathi sokucindezela okukhulu ku-pusher, amanye amafutha angakwazi ukungena phakathi kwe-cylinder nomzimba we-pusher, okuholela ekushintsheni kokuvunyelwa kokusebenza.

Idizayini ye-hydraulic pusher (i-hydraulic lifter)

Lapho ikhamera iphuma ku-pusher, i-valve iyaphakama futhi ivale, kulo mzuzu umzimba we-pusher ubhekene nomgudu wamafutha ekhanda le-cylinder, futhi ukucindezela kusilinda kwehla cishe ku-zero.Ngenxa yalokho, amafutha avela ekhanda anqoba amandla entwasahlobo ye-valve yokuhlola futhi ayivule, afake isilinda (ngokuqondile, ekamelweni lokukhipha ngaphakathi kwalo).Ngenxa yokucindezela okudalwe, umzimba we-pusher uyakhuphuka (njengoba isilinda sihlezi ngokumelene nesiqu se-valve) futhi siphumule ngokumelene nekhamera ye-camshaft - yile ndlela igebe elikhethwa ngayo.Esikhathini esizayo, inqubo iyaphindwa.

Ngesikhathi sokusebenza kwenjini, ingaphezulu lamatapethi, amakhamera e-camshaft kanye neziphetho zeziqu ze-valve ziyaguga futhi ziwohloke, futhi ngenxa yokushisa, ubukhulu bezinye izingxenye zendlela yokusabalalisa bushintsha ngandlela thile, okuholela ekushintsheni okungalawuleki. izimvume.Ompompi bama-hydraulic banxephezela lezi zinguquko, bahlale beqinisekisa ukuthi awekho amagebe nokuthi wonke umshini usebenza ngendlela evamile.

Izinkinga zokukhetha nokushintshwa kwama-valve tappets

Noma yikuphiabaphushayo, naphezu kokuphathwa kokushisa kwezindawo zabo zokusebenza, ziguga ngokuhamba kwesikhathi noma ukungasebenzi kahle, okuphazamisa ukusebenza kwenjini.Izinkinga ngama-pusher zibonakala ngokuwohloka kwenjini, okuhlanganisa noshintsho oluthile ngesikhathi se-valve.Ngaphandle, lezi zinkinga zibonakala ngomsindo we-motor, obonakala kalula ngabadwebi abanolwazi.Kodwa-ke, esimweni sezinjini ezinama-hydraulic lifters, umsindo ngokushesha ngemva kokuqala akuyona inkinga.Iqiniso liwukuthi ngemva kokuba injini ingasebenzi, amafutha ashiya ama-tappets namashaneli ekhanda, futhi imizuzwana embalwa yokuqala ayinikezi ukukhetha kwezikhala - lokhu kubonakaliswa ngokungqongqoza.Ngemuva kwemizuzwana embalwa, uhlelo luba ngcono futhi umsindo uyanyamalala.Uma umsindo ubonwa imizuzwana engaphezu kwe-10-12, khona-ke kufanele unake isimo se-pushers.

Amaphusha anesici kufanele ashintshwe kufakwe amasha ezinhlobo ezifanayo nezinombolo zekhathalogi.Ukushintshwa kufanele kwenziwe ngokuhambisana nemiyalelo yokulungiswa nokugcinwa kwemoto, lo msebenzi uhlotshaniswa nokuhlakazwa kwengxenye yekhanda le-cylinder futhi udinga ukusetshenziswa kwethuluzi elikhethekile (lokumisa ama-valve nabanye), ngakho-ke kungcono ngithembele kochwepheshe.Ngemuva kokufaka ama-pushers, kuyadingeka ngezikhathi ezithile ukulungisa ukucaciswa, kodwa uma izingxenye ze-hydraulic zisetshenziswa, asikho isidingo sokugcinwa.

Isikhathi sokuthumela: Jul-14-2023