Imoto ngayinye inesistimu yokushisisa yekhabethe elihambisana nesistimu yokupholisa injini.Ompompi be-heater kagesi basetshenziswa kabanzi ukulawula isitofu namuhla - funda ngalezi zisetshenziswa, izinhlobo zazo, ukwakheka, isimiso sokusebenza, kanye nokukhetha kwazo nokushintshwa kwazo kulesi sihloko.

Uyini umpompi we-heater kagesi?

I-valve yokushisa kagesi (i-valve yokulawula i-heater kagesi, i-valve yokushisa) - ingxenye yesistimu yokushisa yegumbi labagibeli / ikhabethe lezimoto;Ivalvu noma ivalvu yokulawula ukuphakelwa kwesipholile kusuka ohlelweni lokupholisa injini kuya kurediyetha (isishintshi sokushisa) sehitha.

I-crane elawulwa ngogesi ifana ne-mechanical crane, kodwa iqhutshwa injini kagesi eyakhelwe ngaphakathi noma i-solenoid.Lesi sixazululo senze kwaba nokwenzeka ukushiya idrayivu yekhebula futhi usebenzise ukulawula kwe-heater usebenzisa inkinobho.Ama-cranes kagesi enza kube nokwenzeka ukusebenzisa amasu ahlukahlukene wokushisa ikhabethe kanye nokusebenza kwesistimu yokupholisa injini, kuyilapho kulula ukuyisebenzisa, ethembekile ekusebenzeni futhi enomklamo olula.

Izinhlobo, umklamo kanye nesimiso sokusebenza kwe-valve yokushisa kagesi

Ama-valve anamuhla alawulwa ngogesi ahlukaniswe ngamaqembu ngokusho kohlobo lwesici sokuvala kanye nokushayela kwayo, kanye nenani lamasekhethi (futhi, ngokufanele, amapayipi).

Ngokuya ngenani lamasekhethi namapayipi, ama-valve okushisa alandelayo:

• I-Single-circuit/2-nozzle - ama-valve/ama-valve avamile;

• I-Double-circuit / 3-nozzle - ama-valve ezindlela ezintathu.

Ama-valve anamagatsha amabili ama-valve akwazi ukuvula nokuvala kuphela ukugeleza koketshezi.Ku-valve enjalo, ipayipi elilodwa liyipayipi lokungena, elesibili liyipayipi yokukhipha, futhi into yokukhiya itholakala phakathi kwabo.I-valve ye-heater enama-nozzles amabili isetshenziswa ezinhlelweni zokufudumeza zangaphakathi ezivamile, itholakala phakathi kwepayipi le-exhaust lesistimu yokupholisa injini kanye nepayipi lokungena le-radiator yesitofu, ehlinzeka ngokulawula ukugeleza kwesipholile esishisayo.

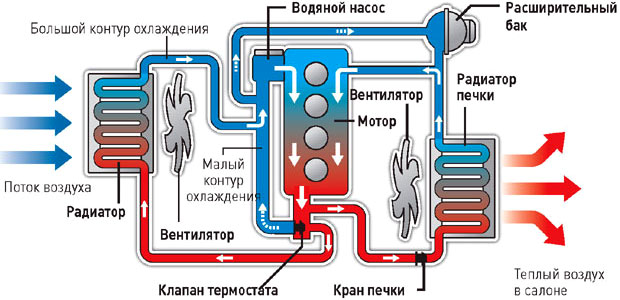

Isikimu esijwayelekile sokupholisa injini kanye nezinhlelo zokufudumeza zangaphakathi

Ama-valve anezindlela ezintathu ama-valve anezinhlangothi ezintathu akwazi ukuqondisa ukugeleza koketshezi kumapayipi amabili ahlukene.Le valve inepayipi elilodwa lokungena kanye namapayipi amabili okukhipha umoya, futhi isici sokuvala siklanywe ngendlela yokuthi sikwazi ukuqondisa uketshezi olusuka epayipini lokungena kwelinye lamapayipi okukhipha umoya, kuyilapho kuvimbela owesibili.I-valve yokushisa enama-nozzles amathathu ingasetshenziswa ezinhlelweni ezihlukahlukene zokushisa zangaphakathi: nge-bypass, ene-heater eyengeziwe, njll.

Ngokusho kohlobo lwesici sokuvala kanye nokushayela kwayo, ama-valve alandelayo:

• Amasango eslayidi ashayelwa injini kagesi;

• Ukuvala okuqhutshwa yi-Solenoid.

Ukwakhiwa kwama-cranes ama-slide kulula.Zisekelwe emzimbeni owenziwe ngepulasitiki onamapayipi, ngaphakathi kwawo kukhona ipuleti elijikelezayo ngendlela yomkhakha oqinile noma umkhakha onezimbobo ngokusho kobukhulu bamapayipi.I-compact motor kagesi ene-gear reducer elula ifakwe emzimbeni, ngosizo lapho ipuleti ijikeleziswa.Kuma-valve anama-nozzles amabili (i-double-circuit), womabili amapayipi atholakala ngokuphambene, phakathi kwawo kukhona ipuleti.Kuma-valve anama-nozzles amathathu, kukhona ipayipi lokungena ngakolunye uhlangothi, namapayipi amabili okukhipha i-exhaust ngakolunye.

I-valve yokushisa enenjini kagesi isebenza kanje.Lapho isitofu sivaliwe, ipuleti yompompi itholakala phakathi kwamapayipi, ivimbela ukugeleza kwamanzi - kulokhu, uketshezi olushisayo alufaki i-radiator yokushisa, uhlelo lokushisa lwangaphakathi alusebenzi.Uma kudingekile ukuvula isitofu, umshayeli ucindezela inkinobho kudeshibhodi, okwamanje kunikezwa injini kagesi ye-crane, iphendulela ipuleti futhi ivule indlela yokupholisa - i-radiator ye-heater iyashisa, ingaphakathi. Isistimu yokushisa iqala ukusebenza.Ukucisha isitofu, umshayeli ucindezela inkinobho futhi, zonke izinqubo zenzeka ngokulandelana, futhi isitofu siyacima.

I-valve yokushisa enezimbobo ezintathu phambi kwe-bypass ohlelweni lokushisa nayo isebenza kalula.Lapho isitofu sicinyiwe, ipuleti elijikayo lisendaweni yokuthi isipholile sidlule kuvalvu bese singena endaweni yokungena yesistimu yokupholisa injini (ipompo) ngepayipi le-exhaust.Lapho isitofu sivuliwe, ipuleti liyaphenduka, livale i-outlet eyodwa bese livula eyesibili - manje ukugeleza koketshezi kudlula ngokukhululekile kurediyetha ye-heater, bese kungena kulo ipayipi lokukhipha umoya kanye ne-inlet yesistimu yokupholisa injini.Lapho isitofu sicinyiwe, zonke izinqubo zenzeka ngokulandelana.

Ukwakhiwa kwama-valve e-solenoid avaliwe kuhlukile.Zisekelwe ebhokisini lepulasitiki, ngaphakathi kwalo kukhona isango eliphakamisayo ngendlela ye-cone encishisiwe.Esimeni esivaliwe, i-shutter ihlala phezu kwesihlalo sayo, iqinisekisa ukuthi ukugeleza koketshezi kuvinjiwe.Isango lixhunywe ngenduku ku-armature ye-solenoid, efakwe emzimbeni we-crane.Ama-valve angama-double-circuit angaba yi-single- and double-solenoid.Esimweni sokuqala, zombili izakhi zokukhiya zitholakala entweni ye-solenoid, okwesibili, into ngayinye yokukhiya ilawulwa yi-solenoid yayo.

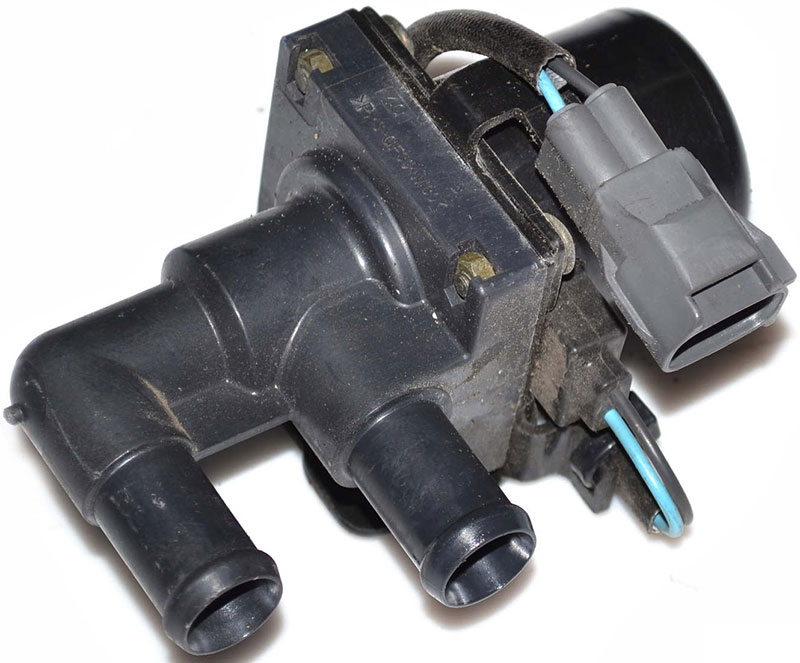

Umpompi we-heater one-solenoid

Ukusebenza kwe-heater solenoid valve nakho kulula.Ama-valve avame ukuvuleka - ngaphandle kwe-voltage ku-solenoid, i-shutter iphakanyiswe isiphethu, isiteshi sivuliwe.Lapho injini iqala, i-voltage isetshenziswa ku-solenoid futhi i-valve iyavala.Lapho isitofu sivuliwe, i-solenoid iphelelwa amandla, umpompi uyavuleka futhi unikeze uketshezi olushisayo kurediyetha.Lapho isitofu sivaliwe, i-voltage iphinda isetshenziswe ku-solenoid futhi umpompi uvale.I-valve ye-double-circuit valve isebenza ngokufanayo, kodwa enye yezifunda zayo ihlale ivala lapho ukuthungela kuvuliwe - lokhu kuvimbela ukunikezwa kwe-coolant ku-radiator ye-heater, uketshezi luhamba eduze kwe-bypass.Lapho isitofu sivuliwe, ama-circuits ashintshiwe, i-coolant ingena ku-radiator yokushisa, lapho isitofu sivaliwe, umpompi ubuyela endaweni yawo yasekuqaleni.Womabili ama-solenoid wevalvu eyindilinga kabili awalokothi avuleke noma avaleke ngesikhathi esifanayo (ngaphandle kokukhishwa kwamandla okuphelele lapho womabili amasango evuliwe).

Imibhobho yama-valve azo zonke izinhlobo i-serrated, lesi simo siqinisekisa ukulingana okuqinile kwamapayipi enjoloba.Ukufakwa kwamapayipi kumapayipi kwenziwa kusetshenziswa izinsimbi zensimbi, i-crane ngokwayo ivame ukulenga ngokukhululekile kumapayipi (ngoba inesisindo esincane).I-crane ixhunywe ohlelweni lukagesi kusetshenziswa isixhumi esijwayelekile sikagesi.

Namuhla, ama-valve okushisa kagesi asetshenziswa kakhulu ezimotweni zasekhaya nezakwamanye amazwe, athathe indawo yama-analogues emishini futhi enza ukulawula kwesitofu sangaphakathi kube lula kakhulu.

Izinkinga zokukhethwa nokushintshwa kwe-valve ye-heater

I-valve yokushisa ibaluleke kakhulu ekusebenzeni kwesistimu yokushisa yangaphakathi / ye-cabin, kodwa ukukhethwa nokufakwa esikhundleni kwalesi sigaba ezimweni eziningi akubangeli izinkinga.Ukukhetha i-crane efanele, kufanele ulandele izincomo ezimbalwa:

• I-voltage yokuhlinzeka yenjini ye-crane kufanele ihambisane ne-voltage yenethiwekhi kagesi engaphakathi ebhodini yemoto - 12 noma 24 V;

• Uhlobo lwe-crane - amapayipi angu-2 noma ama-3 - kufanele ahambisane nohlelo lwesistimu yokushisa yangaphakathi.Kuzinhlelo ezijwayelekile, i-crane enama-nozzles amabili iyadingeka, kumasistimu ane-bypass, i-valve enama-nozzles amathathu iyadingeka.Futhi, i-faucet enama-nozzles amathathu ingasetshenziswa ukudala uhlelo lokushisa nge-heater eyengeziwe;

• Ububanzi bamapayipi kufanele buhambisane nobubanzi bamapayipi ohlelo lokushisa, kodwa uma kunesidingo, ama-adapter angasetshenziswa;

• Kufanele kube nohlobo olulodwa lwesixhumi sikagesi ku-crane kanye nemoto.Uma kunesidingo, kuyadingeka ukufaka esikhundleni uhlobo lwesixhumi emotweni;

• I-crane kufanele ibe nezilinganiso ezifanele zokufakwa kwayo.

Ukushintshwa kwe-valve yokufudumeza kufanele kwenziwe ngemva kokukhipha into epholile, izinsimbi zensimbi kufanele zisetshenziselwe ukufaka.Kuyadingeka ukuqapha ukufakwa okulungile kwe-valve - beka amapayipi ayo okungena kanye nokuphuma ngokuhambisana nesiqondiso se-liquid.Ukuze kube lula, imicibisholo isetshenziswa emibhobolweni ekhombisa isiqondiso sokugeleza koketshezi.Uma i-valve ye-2-nozzle evamile ifakwe ngokungalungile, uhlelo luzosebenza, kodwa ukufakwa okungalungile kwe-valve ye-3-nozzle kuzokwenza uhlelo lungasebenzi ngokuphelele.Ngokufaka okulungile nokuthembekile kwe-crane, isitofu sizoqala ukusebenza ngokushesha, sinikeze ukufudumala nokududuza emotweni.

Isikhathi sokuthumela: Aug-05-2023