Ekusebenzeni komshini we-crank wezinjini ze-piston, enye yezindima ezibalulekile idlalwa izingxenye ezixhuma ama-piston kanye ne-crankshaft - izinduku zokuxhuma.Funda mayelana nokuthi iyini induku yokuxhuma, yiziphi izinhlobo zalezi zingxenye nokuthi zihlelwe kanjani, kanye nokukhetha okulungile, ukulungiswa nokushintshwa kwezinduku zokuxhuma kulesi sihloko.

Iyini induku yokuxhuma futhi ithatha yiphi indawo enjinini?

Induku yokuxhuma iyingxenye ye-crank mechanism ye-piston yezinjini ezivuthayo zangaphakathi zazo zonke izinhlobo;Ingxenye ekhiphekayo edizayinelwe ukuxhuma ipiston kujenali ye-crankshaft ehambisanayo.

Le ngxenye yenza imisebenzi eminingana enjinini:

● Ukuxhumana ngomshini kwepiston ne-crankshaft;

● Ukudluliselwa kusuka ku-piston kuya ku-crankshaft yezikhathi ezivela phakathi ne-stroke yokusebenza;

● Ukuguqulwa kokunyakaza okuphindaphindiwe kwepiston ibe ukunyakaza okujikelezayo kwe-crankshaft;

● I-Lubricant inikezwa iphinikhodi, izindonga ze-piston (ukuze uthole ukupholisa okwengeziwe) nesilinda, kanye nezingxenye zesikhathi kumayunithi amandla ane-camshaft ephansi.

Kumamotho, inani lezinduku zokuxhuma lilingana nenani lamapiston, induku ngayinye yokuxhuma ixhunywe ku-piston (ngokusebenzisa umkhono wethusi nephinikhodi), futhi ingxenye engezansi ixhunywe kujenali ye-crankshaft ehambisanayo (ngokusebenzisa ama-plain bearings).Ngenxa yalokho, kwakhiwa isakhiwo esinama-hinged, esiqinisekisa ukunyakaza kwamahhala kwepiston endizeni eqondile.

Izinduku zokuxhuma zidlala indima ebalulekile ekusebenzeni kweyunithi yamandla, futhi ukuwohloka kwabo kuvame ukukhubaza injini ngokuphelele.Kodwa ukuze ukhethe okulungile nokushintshwa kwalesi sigaba, kuyadingeka ukuqonda ukwakheka nezici zayo.

Izinhlobo nokuklama kwezinduku zokuxhuma

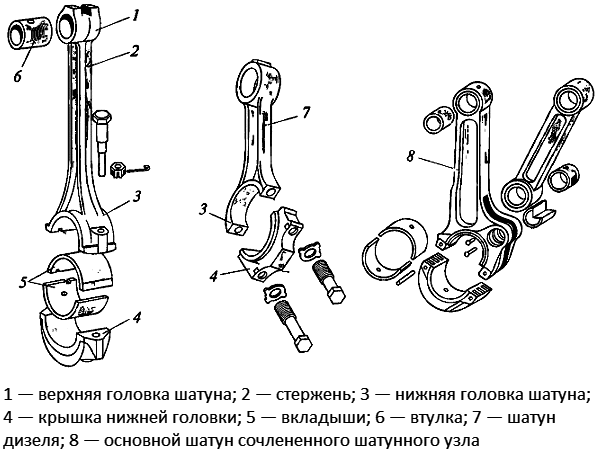

Namuhla, kunezinhlobo ezimbili eziyinhloko zezinduku zokuxhuma:

● Okujwayelekile - izinduku zokuxhuma ezivamile ezisetshenziswa kuzo zonke izinhlobo zezinjini ze-piston;

● Kubhanqiwe (okucacisiwe) - iyunithi ehlanganisa induku evamile yokuxhuma kanye nenduku yokuxhuma encike kuyo ngaphandle kwekhanda le-crank, amayunithi anjalo asetshenziswa kumamotho amise okwe-V.

Idizayini yokuxhuma izinduku zenjini yomlilo yangaphakathi iyasungulwa futhi ifinyelele ekupheleleni (ngangokunokwenzeka ngokuthuthukiswa kobuchwepheshe besimanje), ngakho-ke, naphezu kwezinhlobonhlobo ezinkulu zezinjini, zonke lezi zingxenye zihlelwe ngendlela efanayo.

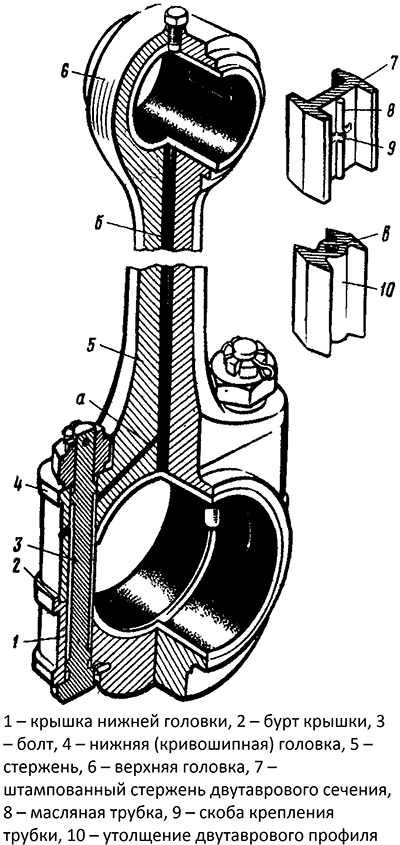

Induku yokuxhuma iyingxenye egoqekayo (ehlanganisiwe), lapho kuhlukaniswa khona izingxenye ezintathu:

● Induku;

● Ikhanda lepiston (elingenhla);

● Ikhanda likaCrank (phansi) elinekhava ekhiphekayo (engasuswa).

Induku, ikhanda elingaphezulu kanye nengxenye yekhanda eliphansi liyingxenye eyodwa, zonke lezi zingxenye zakhiwe ngesikhathi esisodwa ekwenzeni induku yokuxhuma.Isembozo sekhanda eliphansi liyingxenye ehlukile exhunywe kunduku yokuxhuma ngendlela eyodwa noma enye.Ingxenye ngayinye yenduku yokuxhuma inezici zayo zokuklama nokusebenza.

Idizayini yenduku yokuxhuma

Induku.Lesi yisisekelo senduku yokuxhuma ehlanganisa amakhanda futhi iqinisekise ukudluliswa kwamandla kusuka ekhanda le-piston kuya ku-crank.Ubude benduku bunquma ukuphakama kwamapiston nokushaywa kwawo, kanye nokuphakama okuphelele kwenjini.Ukufeza ukuqina okudingekayo, amaphrofayili ahlukahlukene anamathiselwe ezintini:

● I-i-beam ngokuhlelwa kwamashalofu aqondile noma ahambisana nezimbazo zamakhanda;

● I-Cruciform.

Ngokuvamile, induku inikezwa iphrofayili ye-I-beam ene-longitudinal yokuhlelwa kwamashalofu (ngakwesokudla nakwesobunxele, uma ubheka induku yokuxhuma eduze nezimbazo zamakhanda), amanye amaphrofayili asetshenziswa kancane.

Ishaneli ibholwa ngaphakathi kwenduku ukuze kuhlinzekwe amafutha kusukela ekhanda elingezansi kuya ekhanda elingaphezulu, kwezinye izinduku zokuxhuma amagophe aseceleni enziwa kusukela kumzila omaphakathi ukuze kufafazwe uwoyela ezindongeni zesilinda nezinye izingxenye.Ezindongeni ze-I-beam, esikhundleni sesiteshi esiboshiwe, ithubhu yokuhlinzeka ngamafutha ensimbi exhunywe kwinduku enabakaki bensimbi ingasetshenziswa.

Ngokuvamile, induku imakwa futhi imakwe ukuze kufakwe ingxenye efanele.

Ikhanda le-piston.Imbobo iqoshwe ekhanda, lapho kucindezelwa khona umkhono wethusi, odlala indima yokuthwala ithafa.Iphinikhodi ye-piston ifakwe emkhonweni ngegebe elincane.Ukuze ugcobe izindawo zokungqubuzana zephini kanye nomkhono, imbobo yenziwa ekugcineni ukuze kuqinisekiswe ukugeleza kwamafutha kusuka esiteshini ngaphakathi kwenduku yenduku yokuxhuma.

Ikhanda le-crank.Leli khanda liyalahleka, ingxenye yalo engezansi yenziwe ngendlela yekhava ekhishwayo ebekwe phezu kwenduku yokuxhuma.Isixhumi singaba:

● Iqonde - indiza yesixhumi isendaweni efanele endongeni;

● I-Oblique - indiza yesixhumi yenziwe nge-engeli ethile.

| Induku yokuxhuma ngesixhumi sekhava eqondile | Induku yokuxhuma ene-oblique cover connector |

Izingxenye ezivame kakhulu ngesixhumi esiqondile, izinduku zokuxhuma ngesixhumi se-oblique zivame ukusetshenziswa kumayunithi wamandla amise okwe-V nezinjini zedizili, zilungele ukufakwa nokunciphisa ubukhulu beyunithi yamandla.Isembozo singaxhunyaniswa nenduku yokuxhuma ngama-bolts nezikhonkwane, kancane kancane kusetshenziswa iphinikhodi nokunye ukuxhumana.Kungaba namabhawodi amabili noma amane (amabili ohlangothini ngalunye), amantongomane awo ahlanganiswe namawasha okukhiya akhethekile noma izikhonkwane ze-cotter.Ukuqinisekisa ukuthembeka okuphezulu kokuxhumeka, ama-bolts angaba nephrofayili eyinkimbinkimbi futhi ahlanganiswe nezingxenye ezisizayo (i-centering bushings), ngakho-ke izinsimbi zokuxhuma izinduku zezinhlobo ezihlukahlukene aziguquki.

Isembozo singenziwa ngesikhathi esifanayo nenduku yokuxhuma noma ngokwehlukana.Esimweni sokuqala, ngemva kokwakhiwa kwenduku yokuxhuma, ikhanda eliphansi lihlukaniswa libe izingxenye ezimbili ukwenza isembozo.Ukuqinisekisa ukuxhumeka okuthembekile nokuqinisekisa ukuzinza koxhumano uma kwenzeka izikhathi eziguquguqukayo, izindawo zokumisa zenduku yokuxhuma kanye nesembozo zifakwe iphrofayili (zinamazinyo, ngokukhiya unxande, njll.).Kungakhathaliseki ukuthi ubuchwepheshe bokukhiqiza induku yokuxhuma, imbobo ekhanda eliphansi inesithukuthezi emhlanganweni nesembozo, ngakho lezi zingxenye kufanele zisetshenziswe ngababili kuphela, aziguquguquki.Ukuze uvimbele ukuqhuma kwenduku yokuxhuma kanye nesembozo, izimpawu ngendlela yamamaki wezinhlobo ezihlukahlukene noma izinombolo zenziwa kuzo.

Ukuklama izinduku zokuxhuma zezinhlobo ezihlukahlukene

Ngaphakathi kwekhanda le-crank, i-bearing main (i-liner) ifakiwe, eyenziwe ngendlela yama-half-rings amabili.Ukuze ulungise ama-earbuds, kunemifula emibili noma emine (ama-grooves) ngaphakathi kwekhanda, okuhlanganisa amadevu ahambisanayo kuma-liner.Phezulu kwekhanda elingaphandle, i-outlet yamafutha inganikezwa ukuze kufuthwe amafutha ezindongeni ze-cylinder nezinye izingxenye.

Ezindongeni zokuxhuma ezicacisiwe, i-protrusion enembobo eboshiwe yenziwa ngaphezu kwekhanda, lapho iphinikhodi yekhanda eliphansi lenduku yokuxhuma elandelwayo ifakwe khona.Induku yokuxhuma elandelwayo ngokwayo inesisetshenziswa esifana nenduku evamile yokuxhuma, kodwa ikhanda layo eliphansi linobubanzi obuncane futhi alihlukaniseki.

Izinduku zokuxhuma zenziwa ngokugxiviza noma ukubumba, noma kunjalo, isembozo sekhanda eliphansi singaphonswa.Ukuze kwenziwe lezi zingxenye, amamaki ahlukahlukene e-carbon ne-alloy steels asetshenziswa, angasebenza ngokujwayelekile ngaphansi kwemithwalo ephezulu yemishini kanye ne-thermal.

Izinkinga zokunakekelwa, ukulungiswa kanye nokushintshwa kwezinduku zokuxhuma

Izinduku zokuxhuma ngesikhathi sokusebenza kwenjini zingaphansi kokuguga okuncane (njengoba imithwalo eyinhloko ibonakala ngama-liner ekhanda eliphansi kanye nomkhono ekhanda elingaphezulu), futhi ukukhubazeka nokuphuka kuzo kwenzeka ngokungasebenzi kahle kwenjini noma ngenxa ukusetshenziswa kwayo okunamandla isikhathi eside.Kodwa-ke, lapho wenza umsebenzi othile wokulungisa, kuyadingeka ukuhlakaza nokuhlakaza izinduku zokuxhuma, futhi ukulungiswa kweyunithi yamandla kuvame ukuhambisana nokushintshwa kwezinduku zokuxhuma nezingxenye ezihlobene.

Ukuqaqa, ukudilizwa kanye nokufakwa okulandelayo kwezinduku zokuxhuma kudinga ukuhambisana nemithetho ethile:

● Izembozo zamakhanda aphansi kufanele zifakwe kuphela ezindongeni zokuxhuma "zendabuko", ukuphuka kwekhava kudinga ukushintshwa okuphelele kwenduku yokuxhuma;

● Uma ufaka izinduku zokuxhuma, kuyadingeka ukugcina ukuhleleka kwazo kokufaka - induku ngayinye yokuxhuma kufanele ithathe indawo yayo futhi ibe nokuma kwendawo okulungile;

● Ukuqiniswa kwamantongomane noma amabhawodi kufanele kwenziwe ngamandla athile (kusetshenziswa isikrufu se-torque).

Ukunakwa ngokukhethekile kufanele kukhokhwe ekuqondisweni kwenduku yokuxhuma emkhathini.Ngokuvamile kunophawu endongeni, okuthi uma ifakwe kumotho esemgqeni, kufanele ibheke phambili futhi ihambisane nesiqondiso somcibisholo ku-piston.Emamotweni amise okwe-V, emgqeni owodwa, uphawu nomcibisholo kufanele ubheke ohlangothini olulodwa (ngokuvamile umugqa wesobunxele), futhi emgqeni wesibili - ngezindlela ezahlukene.Lolu hlelo luqinisekisa ukulingana kwe-KShM kanye nenjini iyonke.

Uma kwenzeka ukuphuka kwesembozo, uma kwenzeka ku-torsion, ukuphambuka nokunye ukuguqulwa, futhi uma kwenzeka ukubhujiswa, izinduku zokuxhuma zishintshwa ngokuphelele.Induku entsha yokuxhuma kufanele ibe yohlobo olufanayo nenombolo yekhathalogi njengaleyo efakwe ngaphambili emotweni, kodwa le ngxenye isadinga ukukhethwa ngesisindo ukuze kugcinwe ukulinganisa kwenjini.Okufanelekile, zonke izinduku zokuxhuma kanye namaqembu e-piston enjini kufanele zibe nesisindo esifanayo, kodwa empeleni zonke izinduku zokuxhuma, ama-piston, izikhonkwane kanye nama-liner anenqwaba ehlukene (ikakhulukazi uma izingxenye zokulungisa zisetshenziswa), ngakho-ke izingxenye kufanele zikalwe. futhi igcwaliswe ngesisindo.Isisindo sezinduku zokuxhuma sinqunywa ngokucabangela isisindo sekhanda ngalinye.

Ukuhlakazwa, ukushintshwa kanye nokuhlanganiswa kwezinduku zokuxhuma kanye namaqembu okuxhuma ama-rod-piston kumele kwenziwe ngokuhambisana ngokuqinile nemiyalelo yokulungisa nokugcinwa kwemoto.Esikhathini esizayo, izinduku zokuxhuma azidingi ukunakekelwa okukhethekile.Ngokukhethwa okufanele nokufakwa kwezinduku zokuxhuma, injini izohlinzeka ngokusebenza okudingekayo kuzo zonke izimo zokusebenza.

Isikhathi sokuthumela: Aug-05-2023