Ezimotweni ezine-cabover cab, isistimu yokusiza ebalulekile inikezwa - umshini we-rollover onesilinda se-hydraulic njengento yamandla.Funda konke mayelana namasilinda we-cab tipping mechanism, izinhlobo zawo ezikhona kanye nemiklamo, kanye nokukhetha kwawo okulungile nokushintshwa - funda kulesi sihloko.

Iyini i-cab tipping mechanism cylinder?

Isilinda se-cab tipping mechanism (isilinda se-IOC, i-IOC hydraulic cylinder) iyi-actuator yomshini we-tipping cab weloli ngesakhiwo se-cabover;I-hydraulic cylinder esebenza kabili yokukhulisa nokwehlisa ikhebhu.

Isilinda se-MOQ sinemisebenzi eminingana:

- Ukuphakamisa i-cab ukuze ilungiswe noma ilungiswe injini nezinye izinhlelo;

- Ukusiza indlela yokulinganisa ekusekeleni i-cab endaweni egingqikile;

- Ukwehliswa okubushelelezi kwekhebhu ngaphandle kwama-jolt nama-jerk.

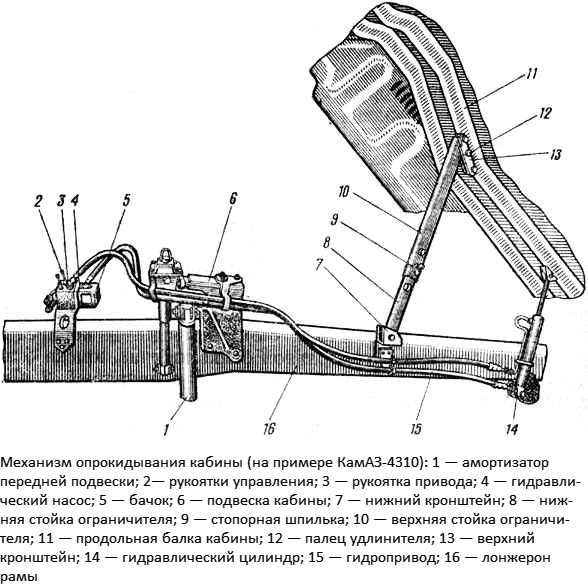

Le cylinder ye-hydraulic iyingxenye ye-cab tipping mechanism (isistimu kwezinye izimoto ihlanganiswe ne-spare wheel lifting mechanism), equkethe iphampu kawoyela eyenziwa ngesandla, amapayipi amabili, indawo yokugcina uketshezi olusebenzayo kanye, empeleni, i-MOK. isilinda.Lo mshini usebenza ngokuzenzakalelayo usuka enjinini nakwamanye amayunithi emoto, ubekwe ngaphansi kwe-cab ku-frame spar.I-cylinder isiza kakhulu futhi isheshise ukugcinwa kwemoto, iqinisekisa izidingo zokuphepha, ngakho-ke uma iphuka, ukulungiswa noma ukushintshwa kufanele kwenziwe ngokushesha ngangokunokwenzeka.Ukukhetha isilinda esifanele se-hydraulic, udinga ukuqonda ukwakheka kwayo, ukusebenza kanye nezinye izici.

Idizayini kanye nesimiso sokusebenza kwesilinda somshini we-cab tipping

Indlela ye-cab tipping

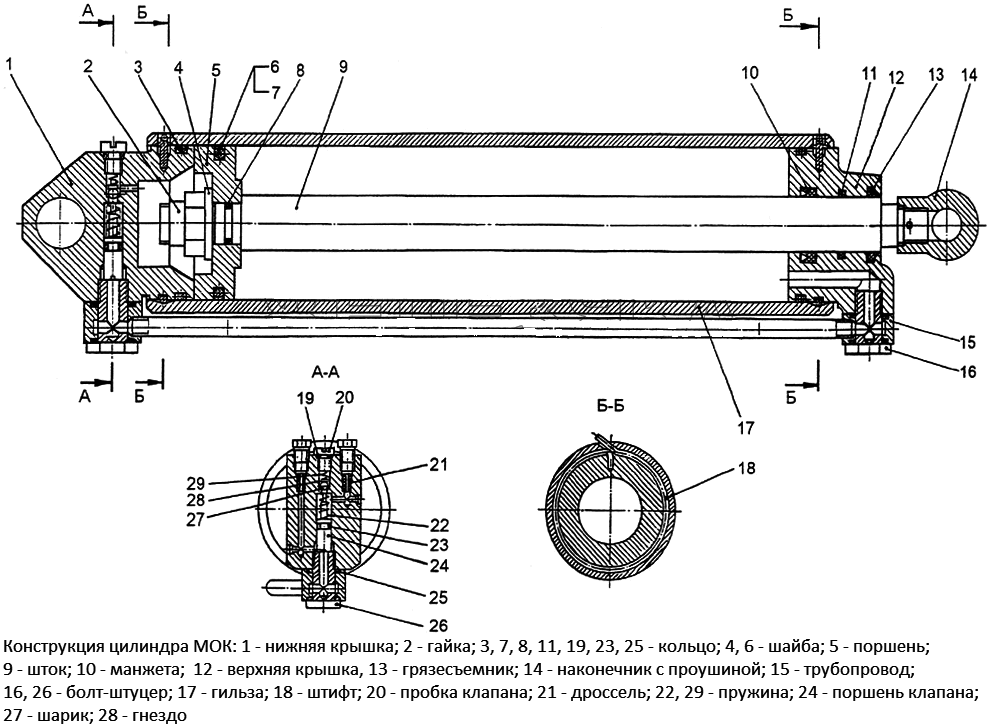

Njengamanje, zonke izimoto ze-cabover zisebenzisa amasilinda we-IOC hydraulic asebenza kabili anomshini owakhelwe ngaphakathi we-hydraulic throttling.Isisekelo sokuklama kwalesi sici siyisilinda sensimbi, esivaliwe kuzo zombili iziphetho ngezembozo.Esembozweni esimboze indawo engezansi yesilinda, kuneso lokuxhomeka okulenga ku-spa yohlaka lwemoto.Ngaphakathi kusilinda kukhona i-piston ene-O-rings, i-piston ixhunywe kwintonga yensimbi edlula isembozo esiphezulu (uphawu luhlinzekwa yi-cuff) futhi iphetha ngeso lokuxhuma kwe-hinge nge-longitudinal beam noma okunye. amandla we-cab.

Kumakhava e-MOK hydraulic cylinder kukhona ukufakwa (noma ama-bolts-fittings) okuxhuma amapayipi.Esembozweni esiphezulu (eceleni kwe-outlet yenduku), ukufakwa ngokushesha kudlulela esiteshini lapho uketshezi olusebenzayo luhlinzekwa khona futhi lukhishwe ku-cylinder.Esembozweni esingaphansi (eceleni kokufakwa kuhlaka) kukhona i-throttle (umhlangano we-throttle) kanye / noma i-valve yokuhlola, ebeka umkhawulo wokugeleza koketshezi olusebenzayo kusuka kusilinda lapho i-cab yehliswa.I-throttle iwukuncipha kwesiteshi esiqoshwe kukhava, umzila ongaguquguquka noma ushintshwe ngesikulufu sokulungisa.I-valve yokuhlola (aka i-hydraulic lock) ivimbela ukuvuza koketshezi olusebenzayo ku-cylinder cavity lapho ikhabethe liphakanyiswa.

Umgomo wokusebenza kwe-MOK hydraulic cylinder ilula.Uma kudingekile ukuphakamisa ikhabethe, iphampu iyajikeleziswa futhi uwoyela ugeleza epayipini ukuya kwesembozo esingaphansi sesilinda, uketshezi ludlula eziteshini lungene kusilinda bese luphusha i-piston - ngaphansi kwesenzo sokucindezela okudalwe ngu. i-liquid, i-piston iyanyakaza futhi iphushe i-cabin ngokusebenzisa induku, iqinisekise ukuchithwa kwayo.Uma kudingekile ukubuyisela i-cab endaweni yayo yasekuqaleni, uwoyela unikezwa isembozo esingaphezulu sesilinda, lapho ungena khona kusilinda bese uphusha i-piston - ngaphansi kwesenzo samandla adaliwe, i-piston ihamba phansi futhi yehlisa ikhab.Kodwa-ke, kune-throttle esembozweni yesilinda esingezansi, okuvimbela uwoyela ukuthi angaphumi ngokushesha emgodini - lokhu kudala amandla anciphisa ijubane lokwehlisa ikhabethe, okuvimbela ukushaqeka nokushaqeka.

Ijubane lokuphakamisa nokwehlisa i-cab lilawulwa yi-throttle kanye ne-valve yokuhlola, lapho izikulufa ezifanele zinikezwa phezu kwekhava ye-IOC cylinder (enekhanda le-slot noma nge-hexagon yesikrini esivulekile) .

Idizayini yesilinda ye-cab tipping mechanism

Ama-cylinders angahlukaniswa ngamaqembu amabili ngokuya ngendlela yokuhlinzeka ngoketshezi olusebenzayo:

- Ngokuxhunywa kwemigqa ngqo phezulu nangaphansi kwesembozo;

- Ngokuxhunywa kwemigqa kwesembozo esisodwa (ngokuvamile kuya phansi) ngokunikezwa kwamafutha kukhava yesibili ngethubhu yensimbi eyakhelwe ngaphakathi.

Amasilinda e-IOC ohlobo lokuqala ahlelwe kalula - kuzo zombili izembozo kukhona ukufakwa lapho amapayipi (hoses) asuka kupompo ye-MOC axhumeke.Amasilinda angama-Hydraulic ohlobo lwesibili ayinkimbinkimbi kakhulu, kokubili okokufakwa kutholakala kukhava engezansi, kodwa ukufakwa okukodwa kuxhunywe epayipini lensimbi lapho uwoyela ugeleza khona kuze kufike ikhava ephezulu.Amadivayisi ohlobo lwesibili enza kube nokwenzeka ukunciphisa ubude bemigqa kawoyela futhi kwandiswe ukuthembeka kwawo, ngoba asendizeni efanayo futhi aguquguquka ngendlela efanayo lapho ephakamisa / ehlisa ikhabethe.

Amasilinda esimanje e-MOK ngokuvamile anezilinganiso ezincane (ubude ebangeni elingama-200-320 mm nobubanzi obungama-20-50 mm) futhi aklanyelwe ukucindezela kwamafutha okungu-20-25 MPa.Amadivayisi womklamo ochaziwe asetshenziswa emalolini asekhaya (KAMAZ, MAZ, Ural) nasezimotweni ezenziwe kwamanye amazwe (i-Scania, IVECO nezinye).

Indlela yokukhetha nokufaka esikhundleni isilinda se-cab tipping mechanism

Ngesikhathi sokusebenza kwe-cabin tipping mechanism, izingxenye zesilinda sawo we-hydraulic ziguga kakhulu, futhi izinhlobo ezahlukahlukene zokuwohloka zingase zenzeke (ukuguqulwa kwenduku nesilinda, ukuqhekeka kwesilinda, ukubhujiswa kwama-eyelets, nokunye) .Uma kwenzeka ukugqoka noma ukungasebenzi kahle, i-cylinder kufanele ilungiswe noma ishintshwe emhlanganweni (okulula namuhla futhi ishibhile).Ukuze ushintshe, kufanele ukhethe isilinda se-IOC yohlobo olufanayo nemodeli eyayisemotweni ngaphambili - lena ukuphela kwendlela yokuqinisekisa ukuthi yonke indlela izosebenza kahle.Lokhu kuyiqiniso ikakhulukazi emalolini amasha, asambozwe yiwaranti.

Kwezinye izimo, kungenzeka ukufaka amasilinda "okungezona ezomdabu", kodwa imingcele eminingana kufanele inakwe lapha:

● Ingcindezi yokusebenza - kufanele ifane neyesilinda endala;

● Ubukhulu bokufaka kanye nobukhulu obuphelele besilinda;

● Indawo nohlobo lwezinto zokufakwa - kufanele zibekwe endaweni efanayo lapho okokufakwa bekukhona kusilinda endala, futhi zibe nobukhulu obufanayo bokuxhuma.

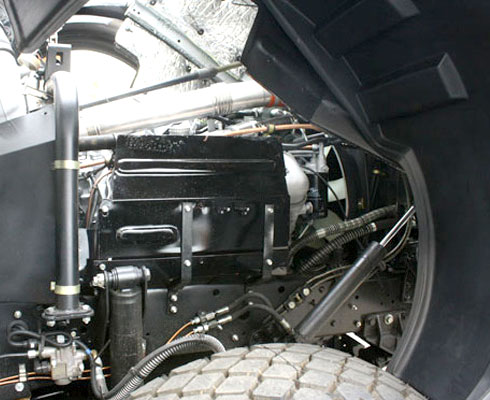

Indawo ye-cwlinder nezinye izingxenye ze-cabtipping mechanism kanye' ne-spare wheel lift

Isilinda esinomfutho ohlukile wokusebenza ngeke sisebenze kahle - kungaba kancane kakhulu, noma ngeke sikwazi ukuhlinzeka ngokuphakamisa nokwehlisa ikhebhu ngokushelelayo.Uma isilinda esisha sinokufakwa kwamanye amasayizi, khona-ke amathiphu amapayipi kufanele nawo ashintshwe.Futhi ngeke kwenzeke ukufaka isilinda sabanye osayizi ngaphandle kokushintsha izibophelelo kukhebhu noma ifreyimu, ngakho iyunithi entsha kufanele ibe nobude obufana nendala.

Ukushintshwa kwesilinda se-MOK kufanele kwenziwe ngokuhambisana nezidingo zebhukwana lokulungisa nokugcinwa kwale moto ethile.Kungakhathaliseki ukuhleleka komsebenzi, okokuqala kudingekile ukuphakamisa ikhabethe futhi uqinisekise ukulungiswa kwayo, ukulungiswa kwayo okuthembekile ngosizo lwamadivayisi afanelekile, kanye nokukhipha uketshezi olusebenzayo ohlelweni.Ngemuva kokufaka isilinda esisha, udinga ukuthululela uwoyela ethangini bese upompa uhlelo (wehlisa bese uphakamisa i-cab izikhathi eziningana).Ngaphezu kwalokho, kungase kudingeke ukulungisa i-throttle (uma lokhu kuhlinzekwe ngokuklama kwe-hydraulic cylinder) - kufanele futhi yenziwe ngokuhambisana nemiyalelo futhi kucatshangelwe isisindo nezici ze-cab.

Ukwandisa impilo yesevisi ye-MOK hydraulic cylinder kanye nayo yonke indlela, ukugcinwa okujwayelekile kufanele kwenziwe.Ngezikhathi ezithile kuyadingeka ukuhlola isimo se-cylinder ukuvuza ngezimpawu zikawoyela, ukufakwa nezinye izingxenye, kanye nokukhubazeka nokulimala.Udinga futhi ukuqapha izinga loketshezi olusebenzayo, uma kunesidingo, uligcwalise.

Ngokukhetha okulungile kanye nokushintshwa kwesilinda, indlela yokunikeza ikhebhu izosebenza ngokushesha nangokuthembekile, iqinisekisa ukusebenza kalula nokuphepha.

Isikhathi sokuthumela: Jul-26-2023